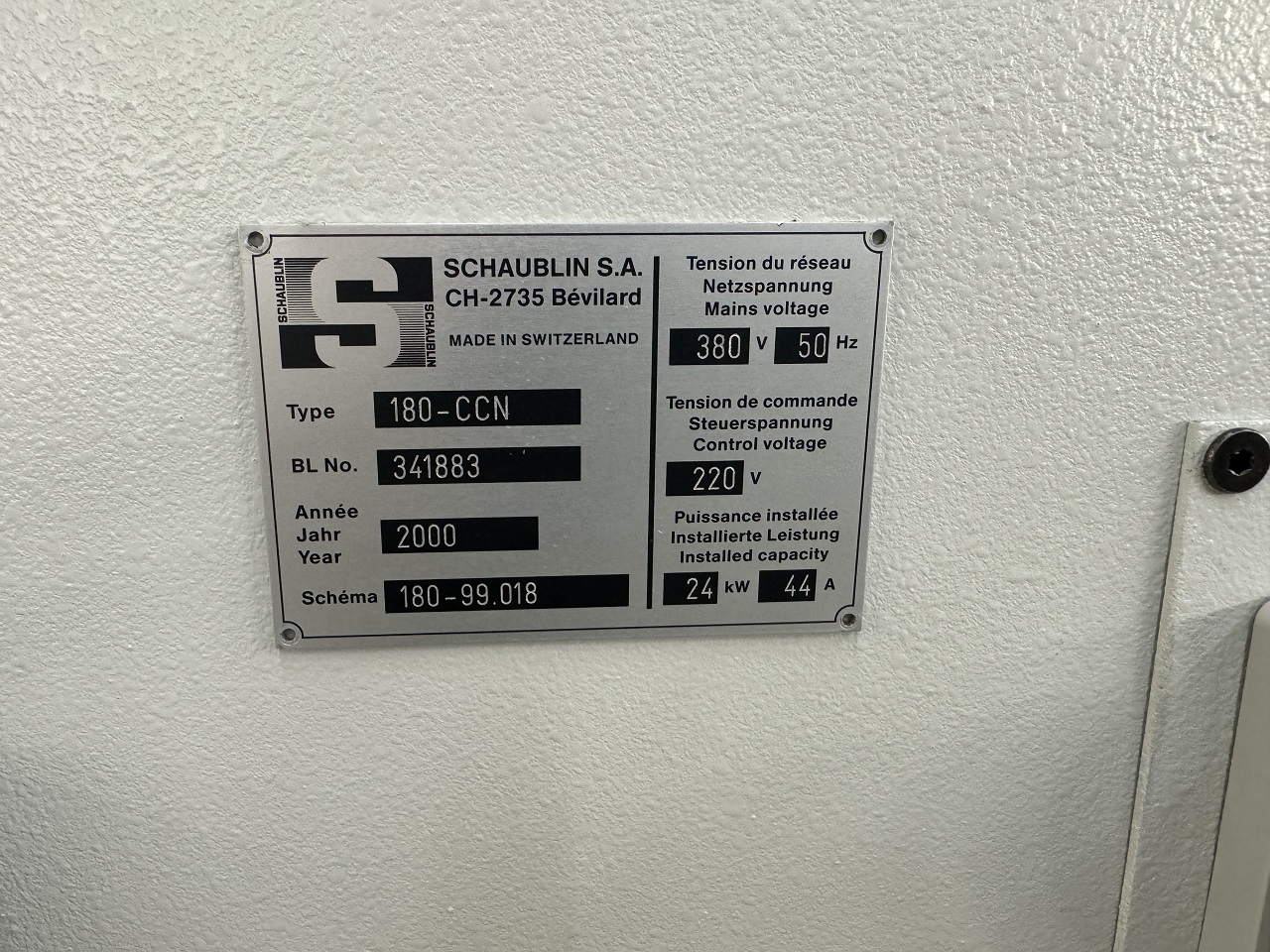

CCN LATHE “SCHAUBLIN” TYPE 180-CCN R-TM A2-6

SKU: 2230043Mfg. 2000, NC Fanuc 18i

Request a quotation

Inventory 2230043 including :

1 Fanuc 18i control unit

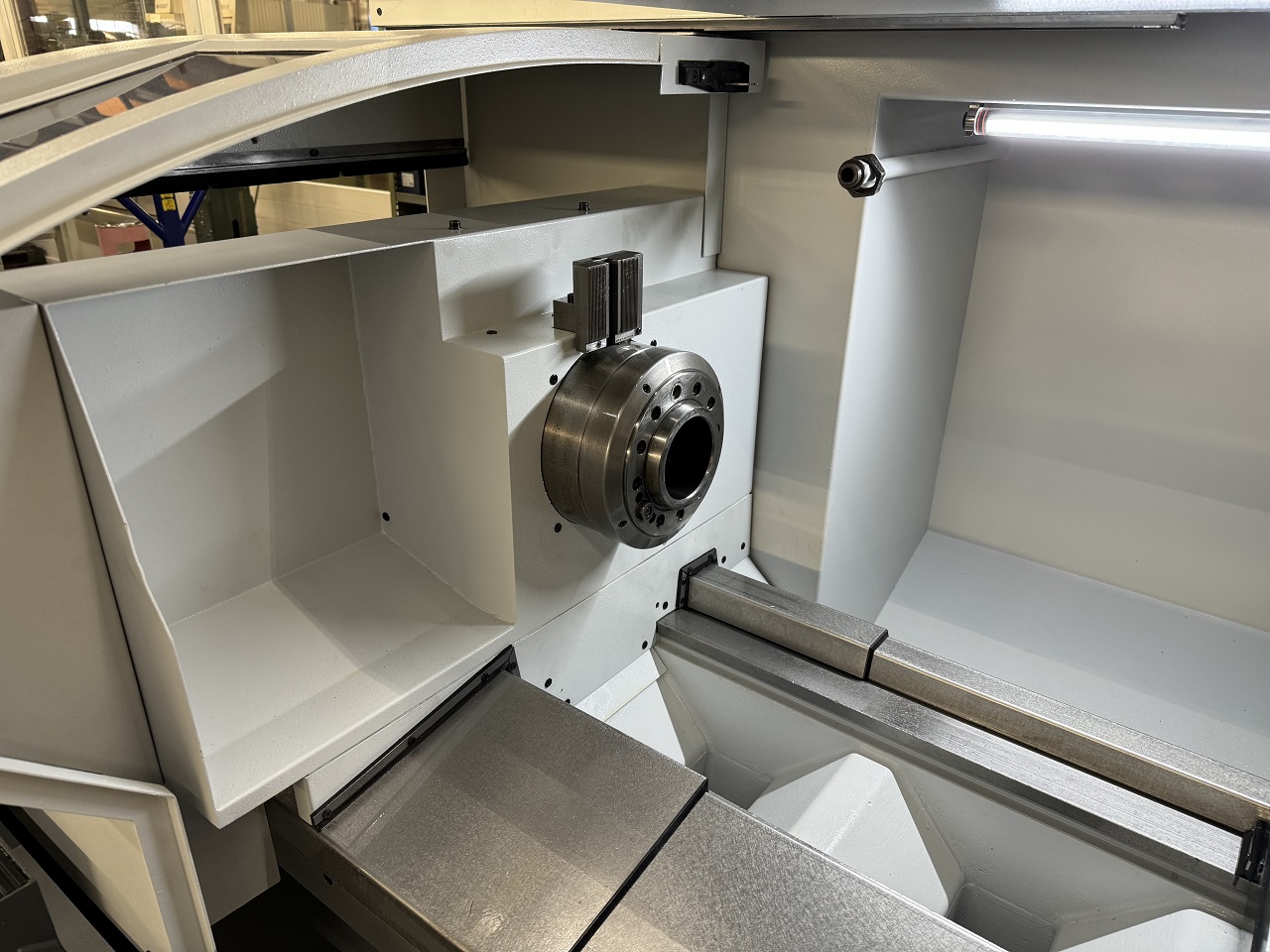

1 A2-6 spindle headstock

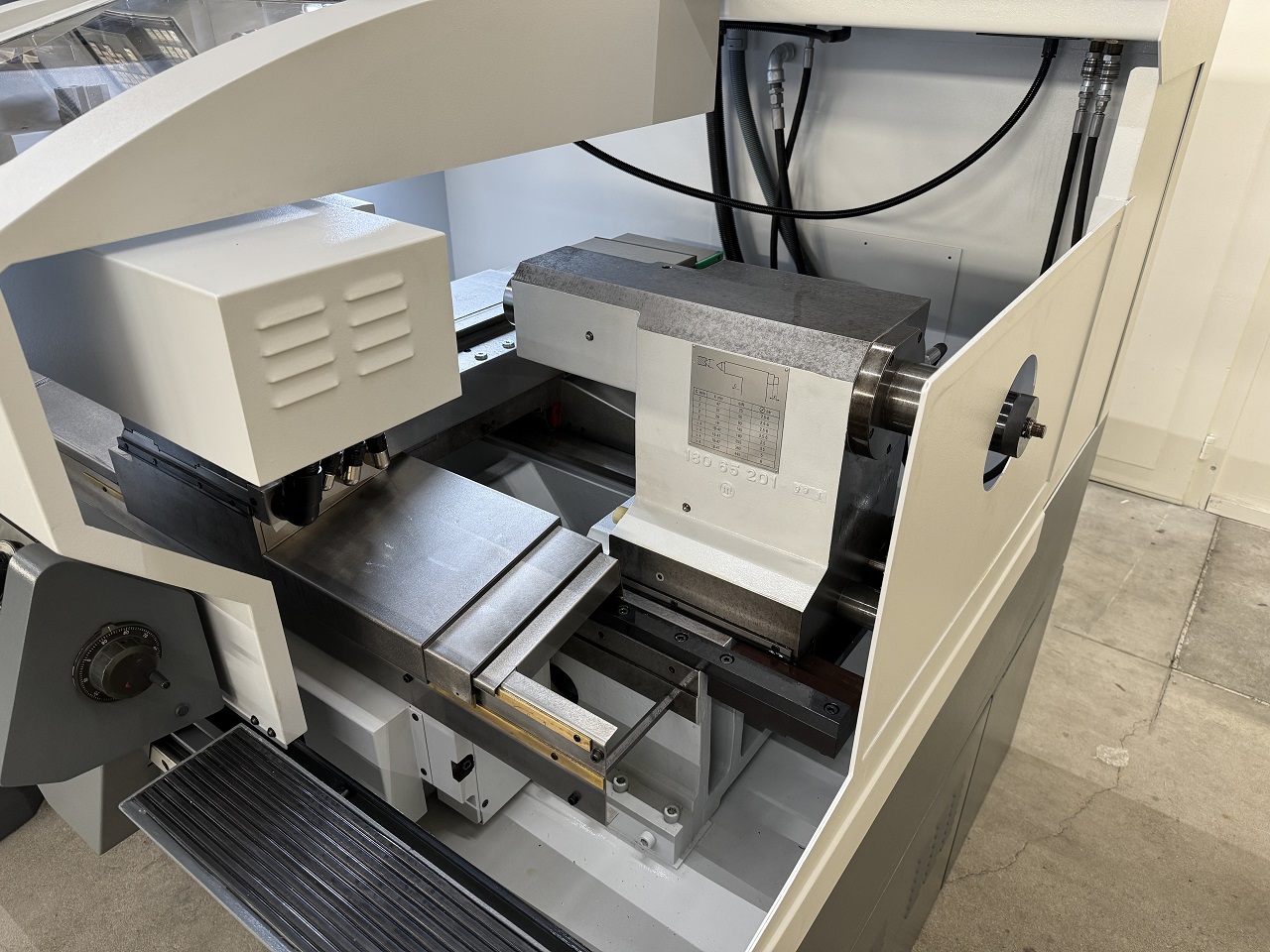

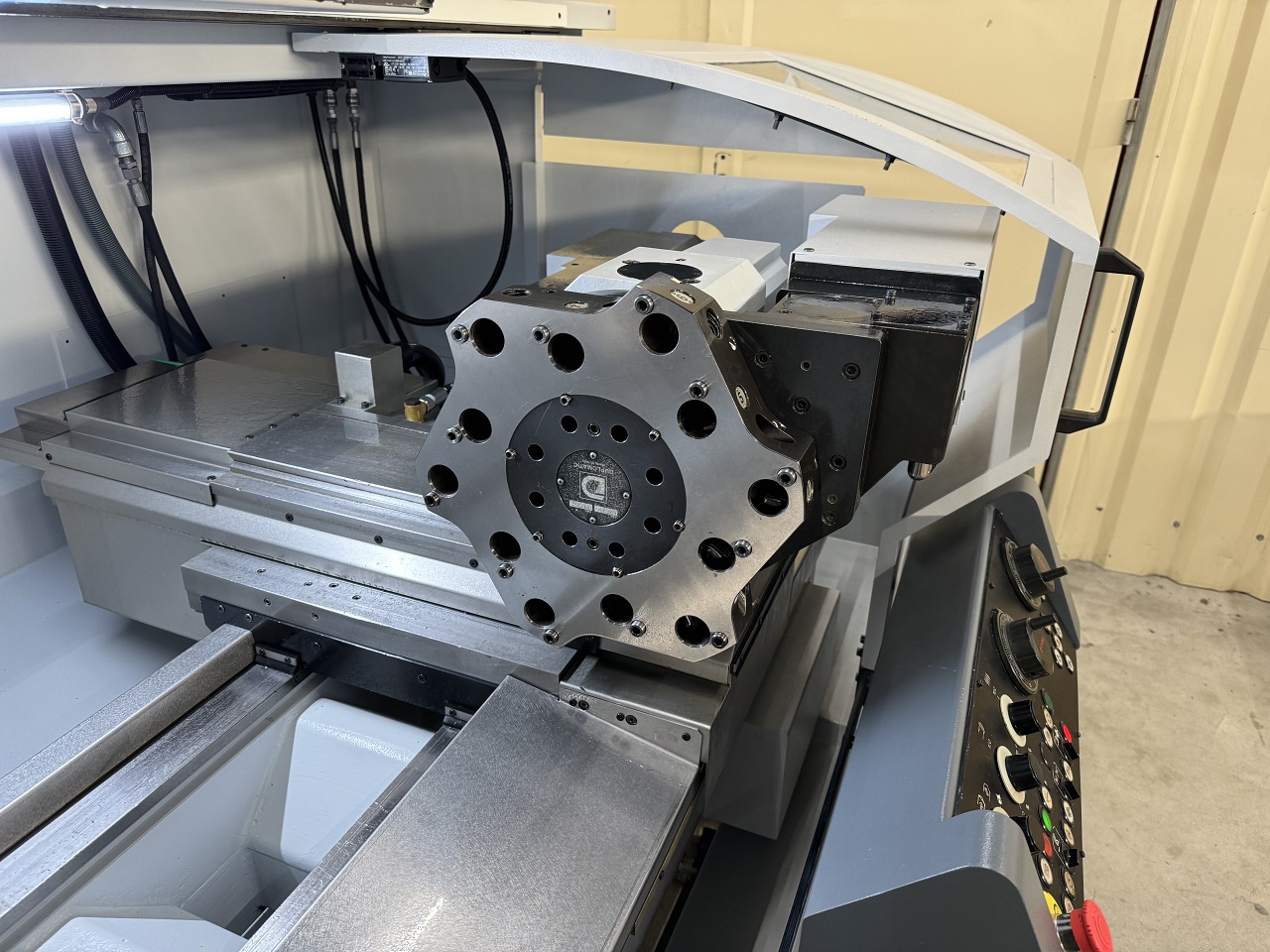

1 VDI 30 12-position revolver for 6 rotating tools

1 pneumatically operated tailstock 180-65.200

1 SCHUNK Rota-s 200-52 A2-6 1×3 jaw chuck

1 Brucker CM5 full rotary tailstock

1 radial drilling-milling head ESX-25 max speed 5000 min-1 without nut EX ref 4100.00552

1 ESX-25 axial drilling-milling head max speed 5000 min-1 without nut EX ref 4100.00550

1 KENNAMETAL ESX-25 spindle without EX nut

1 EWS ESX-25 spindle without EX nut

4 toolholders radial left, short Form B2 ref 4100.0100

1 ESX-25 collet holder, form E3 with nut EX25 with Ø 5 mm collet

1 dito without nut EX25

3 tapping collets Ø 4.5 – 6 and 8 mm

1 tool holder for reversible insert drills Ø 40 mm bore, form E1 ref 4100.00124

1 reamer Ø 32 mm ref 4100.00107

1 Ø 20 mm reamer ref 4100.00105

1 boring bar tool holder Ø 8 mm form E2 ref 4100.00108

1 dito Ø 10 ref 4100.0109

1 dito Ø 12 ref 4100.0110

2 dito Ø 16 ref 4100.0111

1 dito Ø 20 ref 4100.0112

1 dito Ø 25 ref 4100.0113

1 dito Ø 32 ref 4100.0115

1 dito Ø 32 GARANT long

5 Z2 steel protection plugs ref 4100.00130

1 left-hand axial tool holder, force C4 ref 4100.00103

1 pneumatically operated tailstock MT 5 ref 180-65.200

1 microscope support ref 180-60.005

1 coolant device

OPTION

1 travelling steady rest with 3 jaws for Ø 30 – 120 mm ref 180-70.200 chf. 2'500.– + vat

Manufacturing origin Swiss

Voltage 380/50/3

Netweight 2500 kg

Custom position 8458.1120

TECHNICAL DATA

Capacities :

Maximum turning diameter 270 mm

Maximum swing over carriage 160 mm

Height of centres over carriage 83 mm

Maximum swing over bed 430 mm

Turning length between centres (according to equipment) 630 mm

Headstock :

Standardized spindle nose, for use of several collets and jaw-chucks by means of adapter sleeves

Accessories for SCHAUBLIN collets B45/F66

Maximum throughbore, dia. 36 mm/60 mm

Diameter of standard chck 210 mm

Direct AC motor drive, power at 100%/50% duty factor 15/18,5 kW

Max. torque at 100%/50% duty factor 135/165 Nm

Spindle speeds, stepless 4000 min-1

Spindle positioning increment 0,1°

C Axis :

Programmable increment 0,001°

Spindle locking 80 Nm

Pneumatic closing Cylinder, maximum 5 bar, maximum clamping force 3400 daN

Apron and carriage :

Transverse stroke (X-axis) 230 mm

Rsolution, on radius 0,0005 mm

AC motor drive, torque 3 Nm

Ball screw, dia. x pitch 32 x 5 mm

Longitudinal stroke (Z-axis) 720 mm

Resolution 0,001 mm

AC motor drive, torque 6 Nm

Ball screw, dia. x pitch 32 x 10 mm

Feeds :

Working feeds, X-/Z-axis, stepless 0-5000 mm/min

Rapid feed, X-/Z-axis 8/10 m/min

Feed pressure, X-/Z-axis 420/670 daN

Tooling system Turret :

Number of tool stations 12

Number of powered tool stations 6

AC motor drive, power in intermittent service 3,7 kW

Torque max., intermittent 36 Nm

Speed drive, max. 5000 min-1

Standardized fixing of toolholders VDI 30

Maximum tool size 20 x 20 mm

Integrated cooling

Indexing in both senses of rotation

Coolant supply :

Capacity of coolant tank 120 litres

Pump power 10 l/min

Pressure 5 bars

errors and omissions excepted data gived without obligation

| Type | 180-CCN R-TM A2-6 |

|---|