CYLINDRICAL GRINDING MACHINE STUDER S30-1

SKU: 2230022Centres height 125 mm., between centres 650 mm

Completely overhauled:

Mechanics, geometry, hydraulics and electrical parts (checked and/or replaced)

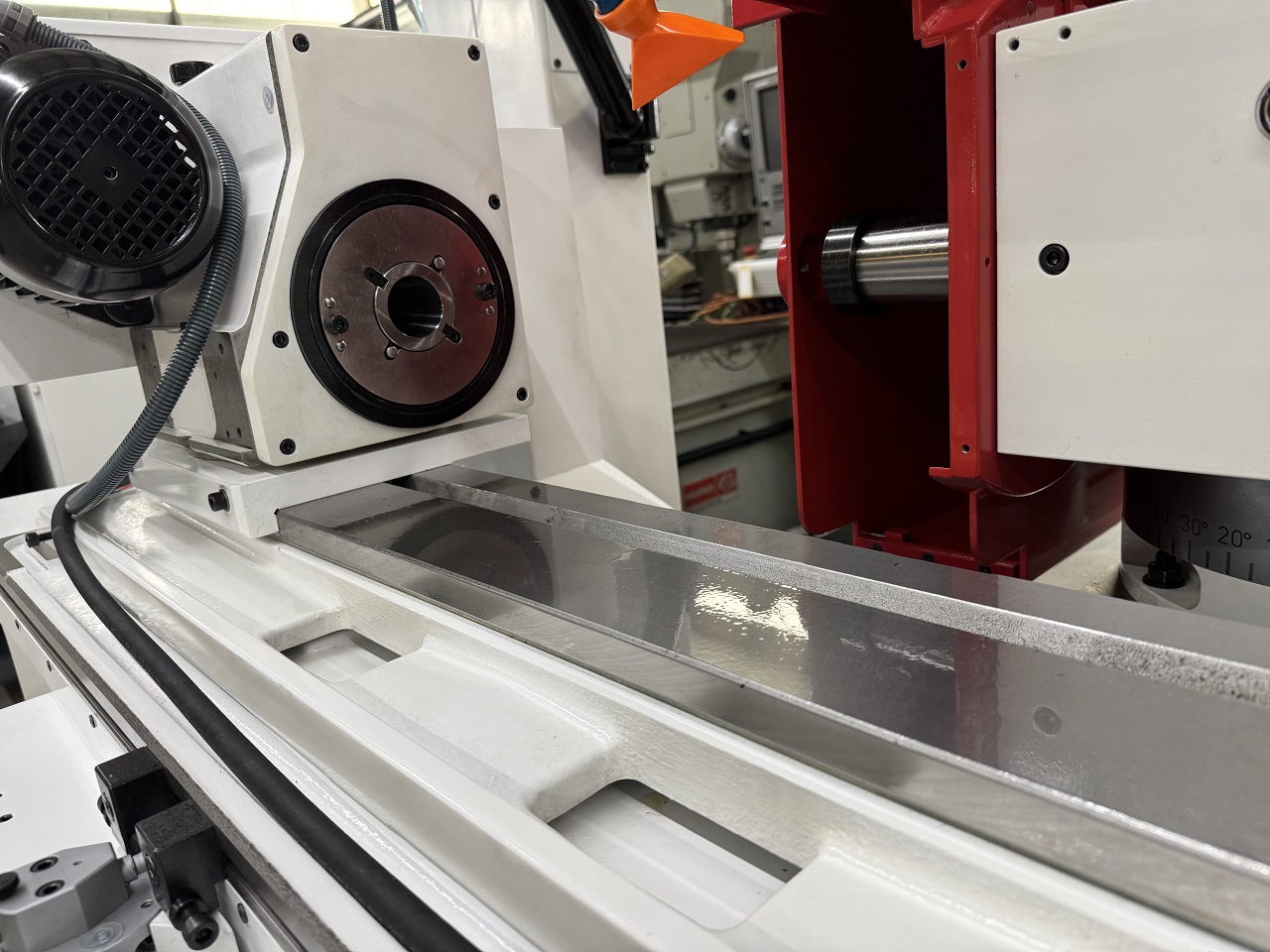

Grinding headstock

Dismantling, cleaning parts, replacing worn and defective parts, overhauling the motor, replacing bearings, replacing belts, dismantling spindle, replacing seals and O-Rings + adjustment. New paintwork.

Headstock

Dismantle, clean parts, replace worn and faulty parts, replace motor, replace belts. New spindle bearings. New paintwork.

Tailstock

Dismantle, clean parts, replace worn and faulty parts, replace motor, replace belts. New spindle bearings. New paintwork.

Internal grinding device

Dismantling, cleaning parts, replacing worn and defective parts, fitting support and aligning geometry. New paintwork.

Hydraulics

Dismantle, replace motor, replace hoses, defective and worn parts. Check hydraulic block

X axis

Dismantling, replace worn parts such as O-Ring, seals, rings etc., overhaul hydraulic piston, rectify tables.

Z axis

Dismantling, grinding the tables, replacing worn and defective parts, overhauling the hydraulic piston, scraping the V and flat guides. New paintwork.

Measuring system

2-axis digital display included

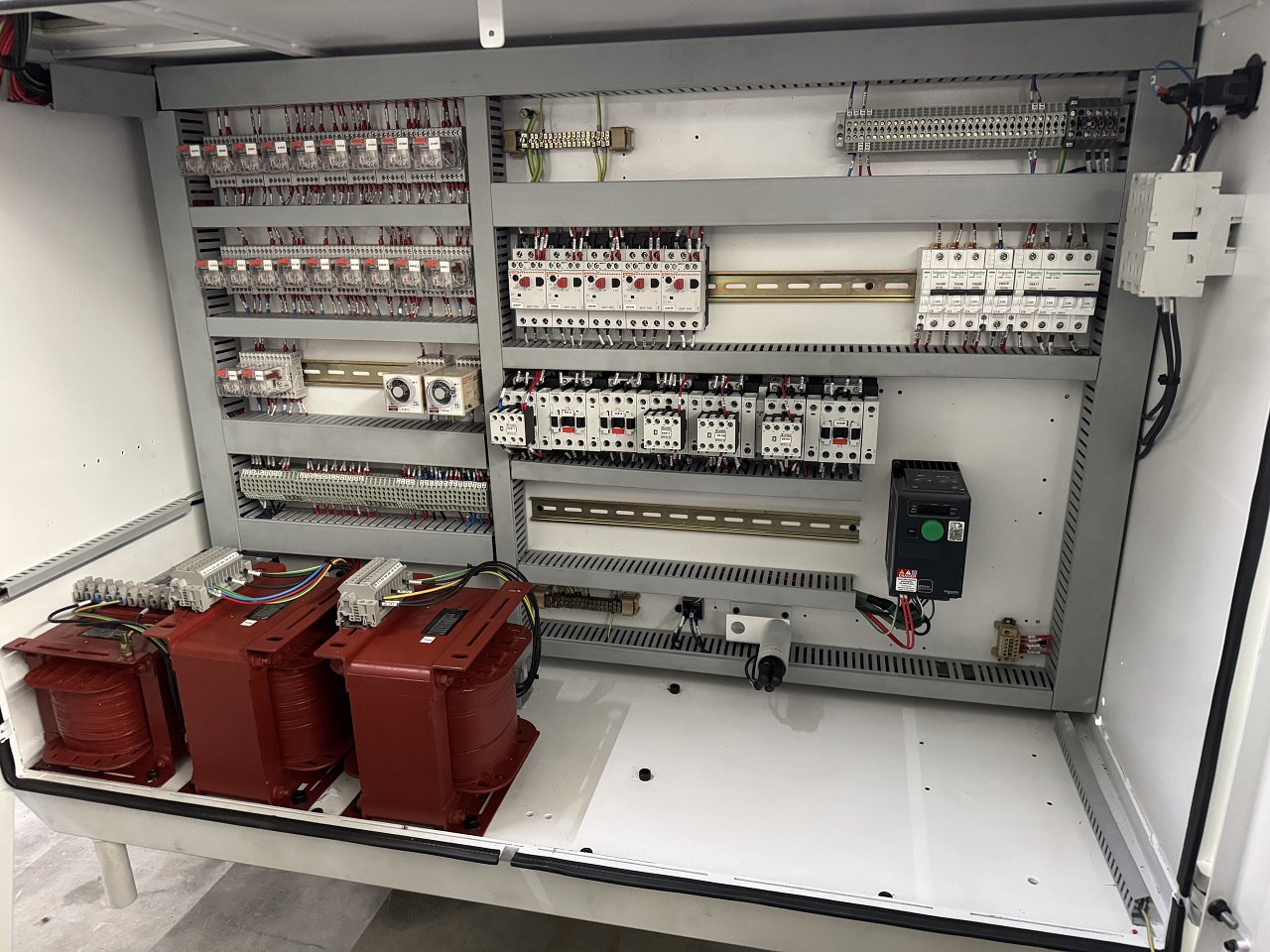

Electrical cabinet

Replace motor terms and relay controls. New wiring. New variable speed drive for workpiece stern.

Paint

Colours: White RAL 9003 and grey RAL 7011

Geometry according to manufacturer's protocol.

Request a quotation

Inventory no. 2230022, equipped with :

1 Workpiece headstock MT5

1 Grinding headstock

1 MT3 tailstock with male center MD MT3

1 Heidenhain ND 730 2-axis digital readout

1 Adjustable dressing device on tailstock A2415728A-O

1 Lighting device

1 SENSITRON control unit 2402.607

1 Internal grinding device with spindle UJ 50 23'000 min-1 overhauled

3 grinding wheel holder

1 collet holder E20 with 7 collets E20

1 Reduction sleeve 100/40 mm

2 Wheel flanges 400 mm bore 127

1 extractor

1 balancing arbor

5 levelling elements

Manufacturing origin Swiss

Voltage : 380/50/3

Netweight 3100 kg

Dimensions 230x155x170cm

Total power : 13 kva

Custom position : 8460.2920

TECHNICAL DATA

MAIN DIMENSIONS

Centre height 400-650-1000-1600 mm

Travel 450-700-1050-1650 mm

LONGITUDINAL SLIDE

Max. travel : + 50 mm

Min. automatic travel 1,5 mm

Speed 50-5500 mm/min

Reversal dwell 0-6 sec

Max. swivel of table 12°/10°/8,5°/6°

Air cushion of table and of workhead

WHEELHEAD SLIDE

Max. travel : 300 mm

Rapid approach 60 mm

Plunge depth in diameter 3,4 mm

Infeed 1 0,012-6 mm/min

Infeed 2 0,012-1,2 mm/min

Incremental infeed 0,001-0,05 mm

WHEELHEAD

External grinding wheel left 400x80x127 mm

Power requirement 5,5 kW

Peripheral speed 35 m/sec

RPM : 1670/2110 min-1

Internal grinding attachment for belt spindles incl. drive

WORKHEAD

Swivel range 0-90°

Speed stepless 30-1000 min-1

Fitting taper Morse 5

Collets : W-25

Power requirement 0,55 kW

Max. workpiece weight between centres 130 kg

Live grinding load 100 Nm

TAILSTOCK

Fitting taper Morse 3

Travel of barrel 35 mm

Fine adjustment for cylindricity corrections +- 40 um

GUARANTEED ACCURACY

Surface straightness over 630 mm 0,003 mm

Roundness on live spindle 0,0003 mm

CONNECTION LOADS

Total power requirement max. 13 kVA

Max. permissible voltage fluctuations -15% +10%

Max. permissible frequency fluctuations : +- 3%

Required air pressure 5 bar

errors and omissions excepted-data given without obligation

| Type | S30-1 |

|---|