Subtotal: € 919.39 (incl. tax)

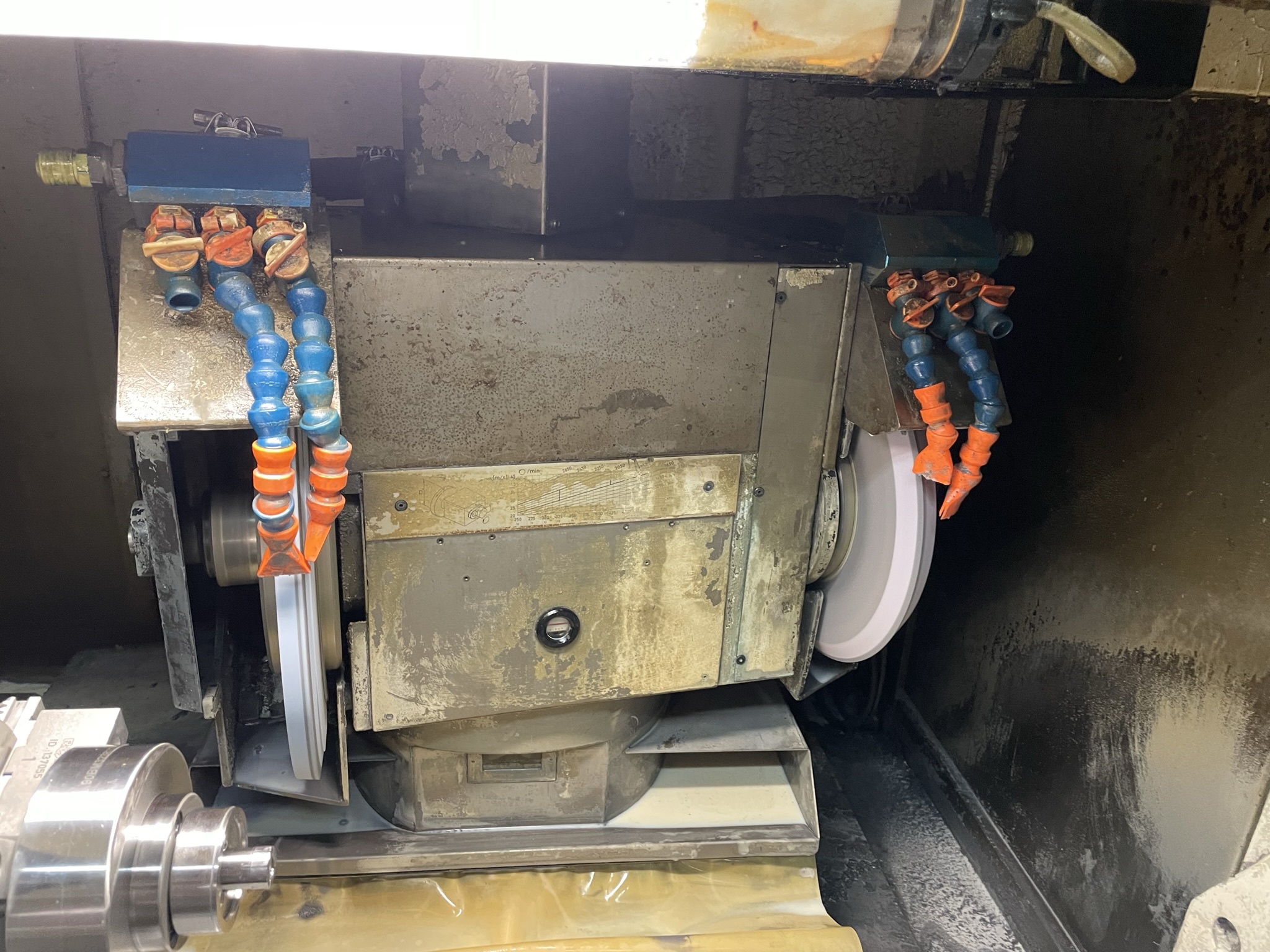

CNC CYLINDRICAL GRINDER KELLENBERGER KEL-VARIA UR 175/1000

SKU: 2240002Year 1999 with Fanuc 18 TB – 3 axes XZB – Marposs E30/E20

Request a quotation

Inventory no. 2240002, machine with :

CNC-control Fanuc 18TB

Grinding wheel equipment left Ø 500 x 80 mm., ref.1310.01

Grinding wheel equipment right Ø 400 x 63 mm., ref.1311.02

Turning part with automatic indexing for type UR, ref. 1022-01

Internal grinding spindle type HJN828 complete, ref. 0013.09 – 28'000 RPM

Hydraulic quill retraction for the tailstock, ref.1030.01

Micro-adjustment on the tailstock, ref. 1030.02

Power clamping device, ref. 1043.01

Dressing device on the lower table, ref. 1050.01

Swivelling diamond holder 10 mm, ref. 0053.05

Marposs gate sensor, ref. 1066.02

Combined measuring control Marposs, ref. 1064-02

Paper tape filter Vertex

Errors and omissions excepted, these data are given to you without obligation.

Manufacturing origin CH

Voltage 400V/50Hz/3ph

Netweight 5500 kg

Custom position 8460.2300

Dimensions 410x226x212 cm

TECHNICAL DATA

Numerical control Fanuc 18TB

Intermediate part

Pivoting part with automatic indexing 2.5° with R / RS / UR / URS -210° to +30

B axis, resolution 0.1″ : with R / RS / UR / URS -210° to +30

Standard workhead

Pivoting range -10° to +100

Spindle speed (continuous) 6 – 600 min-1

Internal taper attachment MT5

Reduction sleeve MT5/MT4

External short taper attachment : DIN 55026 / Gr.5

Permissible load 160 Nm

Guaranteed circularity for chucking work

Standard 0.5 µm

Optional 0.2 µm

Weight of tailstock : 150 kg

Tailstock

Taper attachment MT4

Quill travel 50 mm / 2

Option: micrometric displacement with correction (Ø) : +/- 150 µm)

Wheel data

Diameter 300 27 ms-1

Diameter 400 35 ms-1

Diameter 500 45 ms-1

Workhead UR

Power 9.2 kW / 12.5 HP

Grinding wheel mounting, max. left Ø 500 x 80 mm

Additional right max. Ø 400 x 63 mm

Internal grinding device spindle HJN 828 – 28’000 RPM

Lower table (Z axis)

Distance between centres 1000 mm

Max strokes : 1150 mm

Max. speed 15 m/min

Max. resolution : 0.1 µm

Upper table

Distance between centres 1000 mm 0 to 9° swivel range

Grinding carriage (X axis)

Max travel 320 mm

Max. speed 7.5 m/min

Max resolution 0.1 µm

Pneumatic

Connection min 6 bar

Air consumption approx. : 0.6 m3/h.

Cooling fluid

Connection pressure : max 3 bar

Space required (version 1000) 3600 x 2000 mm

errors and omissions excepted-data given without obligation

MANUEL PRESS "BENZING" TYP HP-225 T

MANUEL PRESS "BENZING" TYP HP-225 T