Subtotal: € 20,782.54 (incl. tax)

Machines

Accessoires

Looking for machine tools?

Scemama sells new and used machine tools.

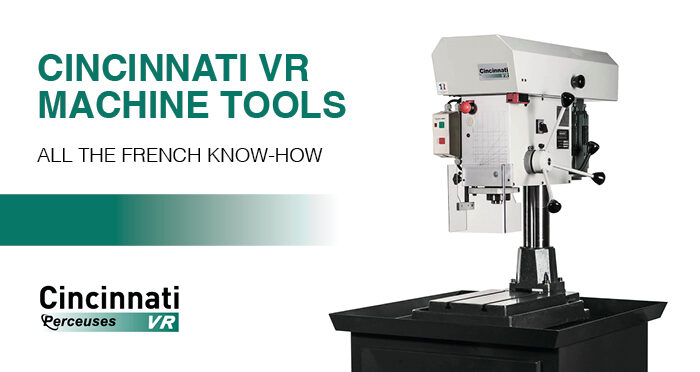

Dealer Schaublin, Cincinnati, Mectron.

Search

We have thousands of machine tools and various accessories in our catalog.

Information

We surely have the machine you need or we can have it.

Second hand

All our machines are checked by our technicians in order to prevent bad surprises.

News

Your Recently Viewed Products

CYLINDRICAL GRINDING MACHINE STUDER S30-1

Between centres 650 mm and centres height 125 mm

2x OD and 1x ID with spindle 45'000 min-1

Completely overhauled:

Mechanics, geometry, hydraulics and electrical parts (checked and/or replaced)

Grinding headstock

Dismantling, cleaning parts, replacing worn and defective parts, overhauling the motor, replacing bearings, replacing belts, dismantling spindle, replacing seals and O-Rings + adjustment. New paintwork.

Headstock

Dismantle, clean parts, replace worn and faulty parts, replace motor, replace belts. New spindle bearings. New paintwork.

Tailstock

Dismantle, clean parts, replace worn and faulty parts, replace motor, replace belts. New spindle bearings. New paintwork.

Internal grinding device

Dismantling, cleaning parts, replacing worn and defective parts, fitting support and aligning geometry. New paintwork.

Hydraulics

Dismantle, replace motor, replace hoses, defective and worn parts. Check hydraulic block

X axis

Dismantling, replace worn parts such as O-Ring, seals, rings etc., overhaul hydraulic piston, rectify tables.

Z axis

Dismantling, grinding the tables, replacing worn and defective parts, overhauling the hydraulic piston, scraping the V and flat guides. New paintwork.

Measuring system

2-axis digital display included

Electrical cabinet

Replace motor terms and relay controls. New wiring. New variable speed drive for workpiece stern.

Paint

Colours: White RAL 9003 and grey RAL 7011

Geometry according to manufacturer's protocol.

SHELL MILL HOLDER "EROGLU" TYPE ISO 40 AD/B Ø32 L50 S

SHELL MILL HOLDER "EROGLU" TYPE ISO 40 AD/B Ø32 L50 S  GRINDING WHEEL "FAG" EFESIS Ø 175X16X50

GRINDING WHEEL "FAG" EFESIS Ø 175X16X50  GRINDING CARRIAGE "SCHAUBLIN" 102-51

GRINDING CARRIAGE "SCHAUBLIN" 102-51  THREADED ADAPTER "MS" ISO50 M-12

THREADED ADAPTER "MS" ISO50 M-12