Subtotal: CHF 886.42 (incl. tax)

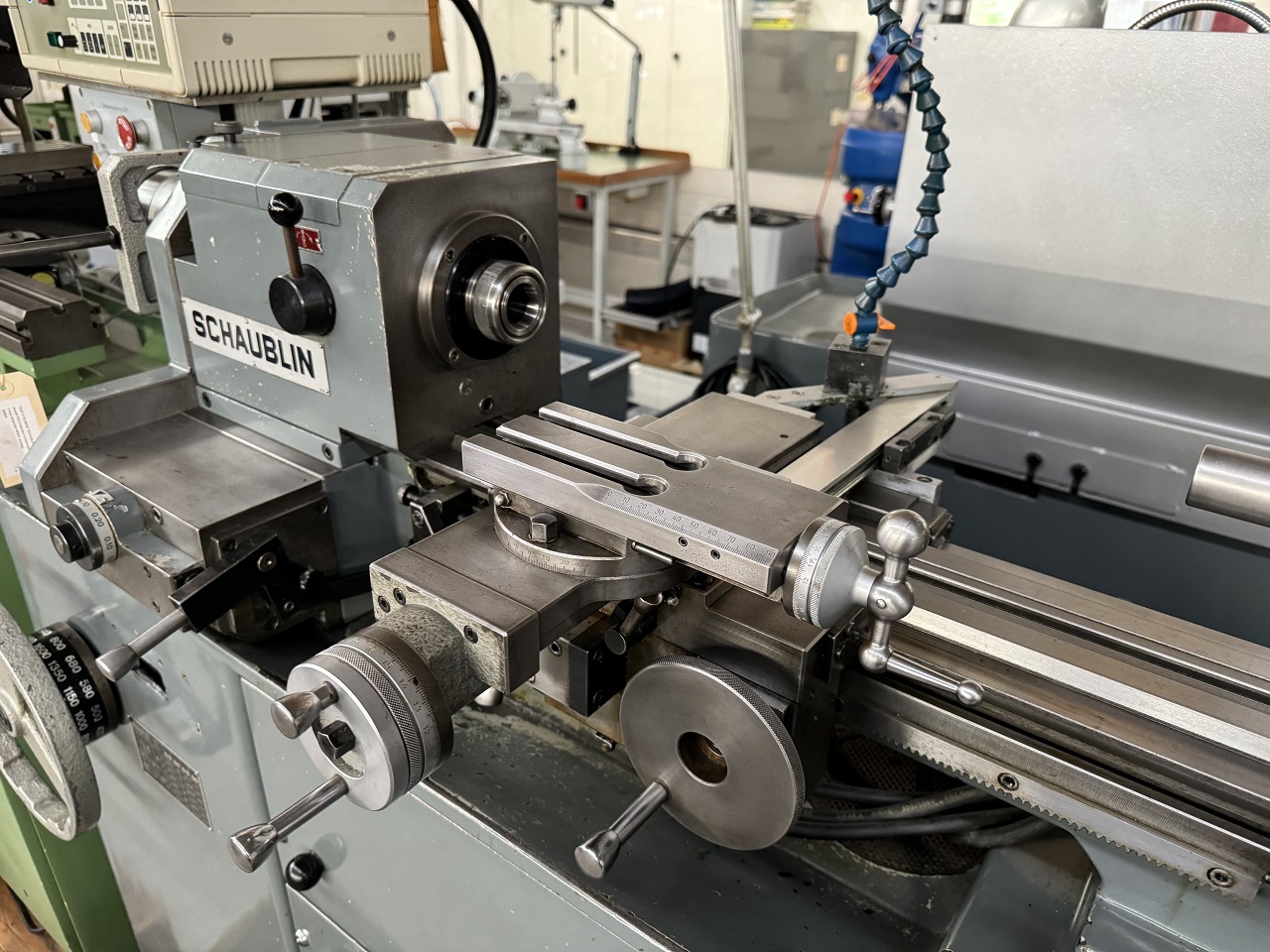

LEADSCREW LATHE “SCHAUBLIN” TYPE 102N-VM W-25

SKU: 2180113Headstock W25 reduction through gears, digital read-out

Request a quotation

Inventory Nr. 2180113, machine’s accessories list :

– 1 headstock W-25 with reduction through gears and fast clamping device

– 1 spindle nose protection W-25

– 1 saddle cross carriage

– 1 tail-stock MT 2

– 1 cast-iron base with 2 pivoting drawers

– 1 electrical equipment 380V

– 1 cooling device

– 1 2-axes digital read-out Heidenhain ND 930

– 1 set of 31 gears

– 1 set of 50 assorted collets

– 1 full center W-25

– 1 driving plate W-25

– 1 2×3-jaws chuck Ø 125 without flange

– 1 drill-chuck flange Ø 150 W-25

– 1 turret Multifix type A

– 2 cutter-holder Multifix type AD 1675

– 1 rotating counter-center MT 2 – full

Origin CH

Netweight base-mounted lathe 550 kg

Voltage : 380V/50Hz/3ph

Dimensions 1550x510x1555 mm

TECHNICAL DATA

:

Capcities :

Height of centres 102 mm

Distance between centres with standard headstock 450 mm

Distance between centres with headstock

incorporating reduction unit 375 mm

Swing over bed 200 mm

Swing over carriage 120 mm

Headstocks :

Spindle nose for collets type SCHAUBLIN W 25

Spindle bore 25 mm

Maximum bore through collet 19 mm

Reduction unit, ratio 1:5

Bed :

Heigh – width – length 168 – 130 – 1000

Cast-iron bed, hardened and ground section of 102 N lathe and dovetail.

Carriage :

Maximum stroke on bed 400 mm

Tool slide width-length 80-194 mm

Stroke (manual traverse) 90 mm

Carriage body guide length on bed 250 mm

Leadscrew :

Leadscrew for turning and screwcutting, dia 40 mm

Leadscrew hardened, thread ground, pitch 4 mm

Turning :

8 longitudianal feeds : 0.02-0.03-0.04-0.06-0.08-0.1-0.2-0.3 mm/rev

Larger geeds obtainable by using screwcutting change gears

Screwcutting :

Maximum pitch (using standard change gear) 4mm

Chart for 20 metric threads 0.25-4 mm

Chart for 25 English threads 80-6 tpi

Screw- and handwheel-operated tailstock :

Spindle diameter 30 mm

Internal spindle taper 2 MORSE

Spindle stroke 80 mm

Steadies :

Capacity of staionary steady 70 mm

Capacity of travelling steady 40 mm

Coolant system :

Tank capacity 23 litres

errors and omissions excepted data given without obligation

3-BIT CHUCK "ROEHM" TYPE 160 6 1/4

3-BIT CHUCK "ROEHM" TYPE 160 6 1/4  GRINDING ATTACHMENT "" TYPE B-8

GRINDING ATTACHMENT "" TYPE B-8  3-BIT CHUCK "" TYPE 165 MM

3-BIT CHUCK "" TYPE 165 MM  DIAL JAUGE "COMPAC" TYPE CL2-532

DIAL JAUGE "COMPAC" TYPE CL2-532