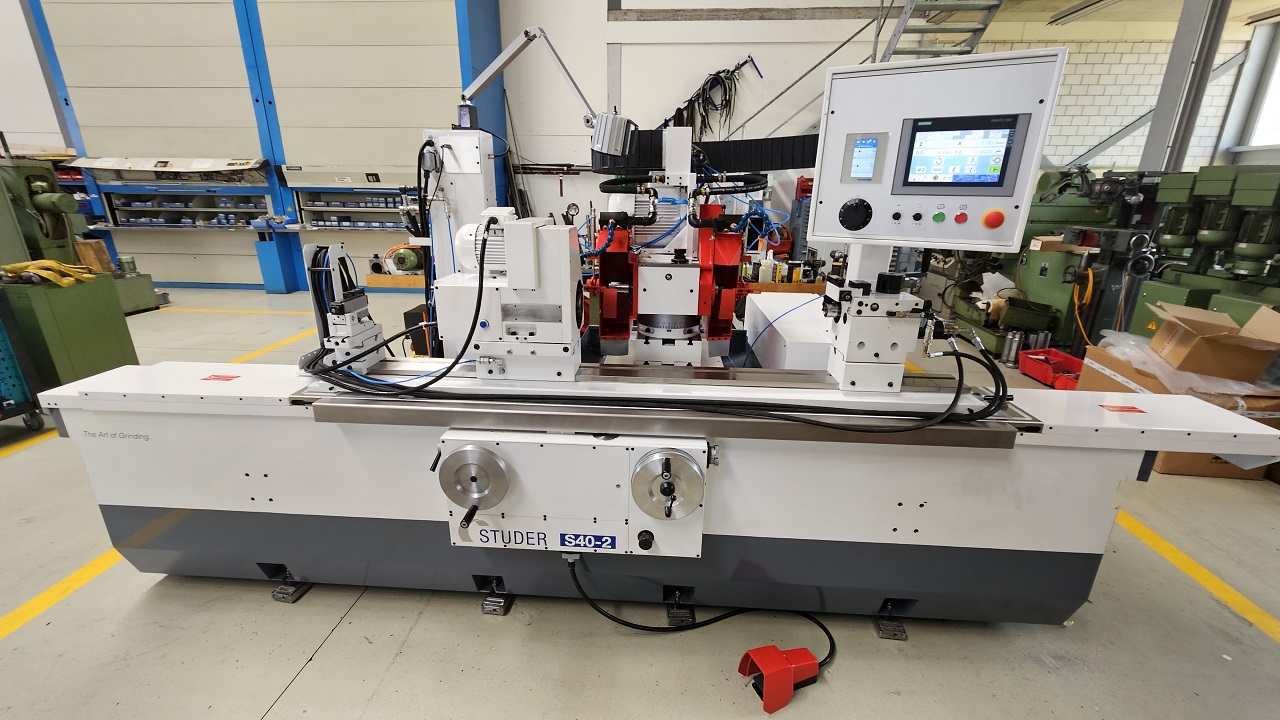

EXTERNAL AND INTERNAL CYLINDRICAL GRINDER “STUDER” S40-2

SKU: 2324015complete retrofit, between centres 1600 mm., centres

Request a quotation

Inventory nr. 2324015, machine equipped as follows

1 STUDER external and internal cylindrical grinding machine

Type S40-2, completely retrofitted

Distance between centres 1600 mm

125 mm centres height

New electrical cabinet with Siemens PLC and 9" touch screen

Left grinding wheel guard 0 400mm B axis resolution every 5° Hydrodynamic workhead

Grinding wheel and workpiece headstock and internal spindle with frequency inverter X-axis speed: 0.012 – 8 mm/min.

Z axis speed: 1OO – 5000 mm/min. Spark erosion time: 0 – 100 sec.

Weight of workpiece between centres: max. 130 kg

Weight of volatile part: max. 100 Nm, including workpiece holder

Accessories incl.:

2 measurement rules

1 Marposs pick-up

1 spanner

1 drive ring (tailstock)

1 spring-loaded drive ring

2 grinding wheel flanges

Including, grinding of 5 diameters in 1 cycle

Consisting of

(Semi-) automatic trueing compensation

Trueing-up autom. with compensation (external)

Semi-automatic training with compensation (internal)

Spindle for internal grinding, on request

1 set of 50 mm heightening soles (to 175 mm), on request

1 filtration tank through paper band, on request

The machine is supplied with the following functions/features:

Z-axis with proportional valve for improved repeatability

Siemens 9'' PLC and touch screen

Wheel dressing with automatic compensation.

For grinding (between roughing-finishing and before finishing).spreading time

Standard service cycles

CE marking

Manual grinding cycles

Retrofit consisting of :

Complete dismantling of the machine

Parts cleaning

Replace all defective and worn parts

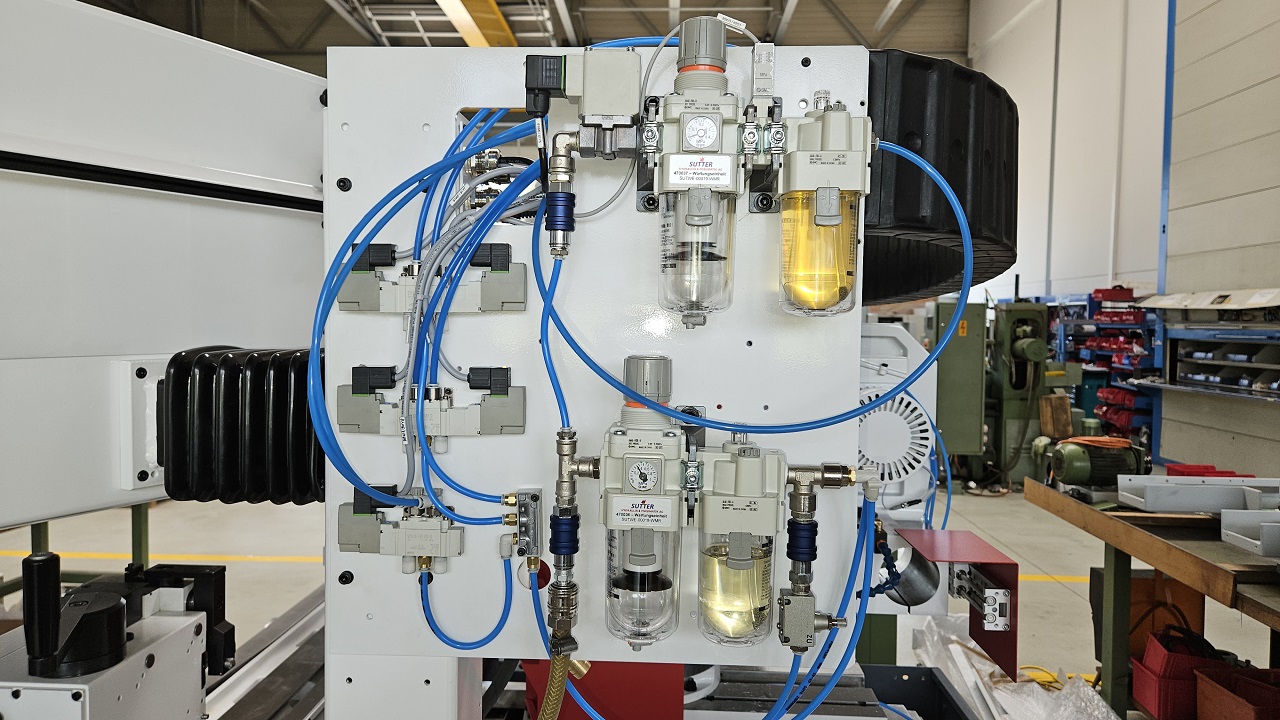

Replace all hydraulic hoses + pome

Install a propositional valve for the Z axis

Overhaul of the grinding wheel headstock, parts headstock and tailstock

Overhaul or replacement of all motors

Replacement and overhaul of the electrical cabinet

PLC installation with touch screen

Including 2 Fagor encoders for X and Z axes

Reconfiguring tables

Geometry as per report/ new

New paintwork RAL 7011 / RAL 9003

Reassembly of all components

Final inspection and testing

Errors or omissions excepted, data given without obligation.