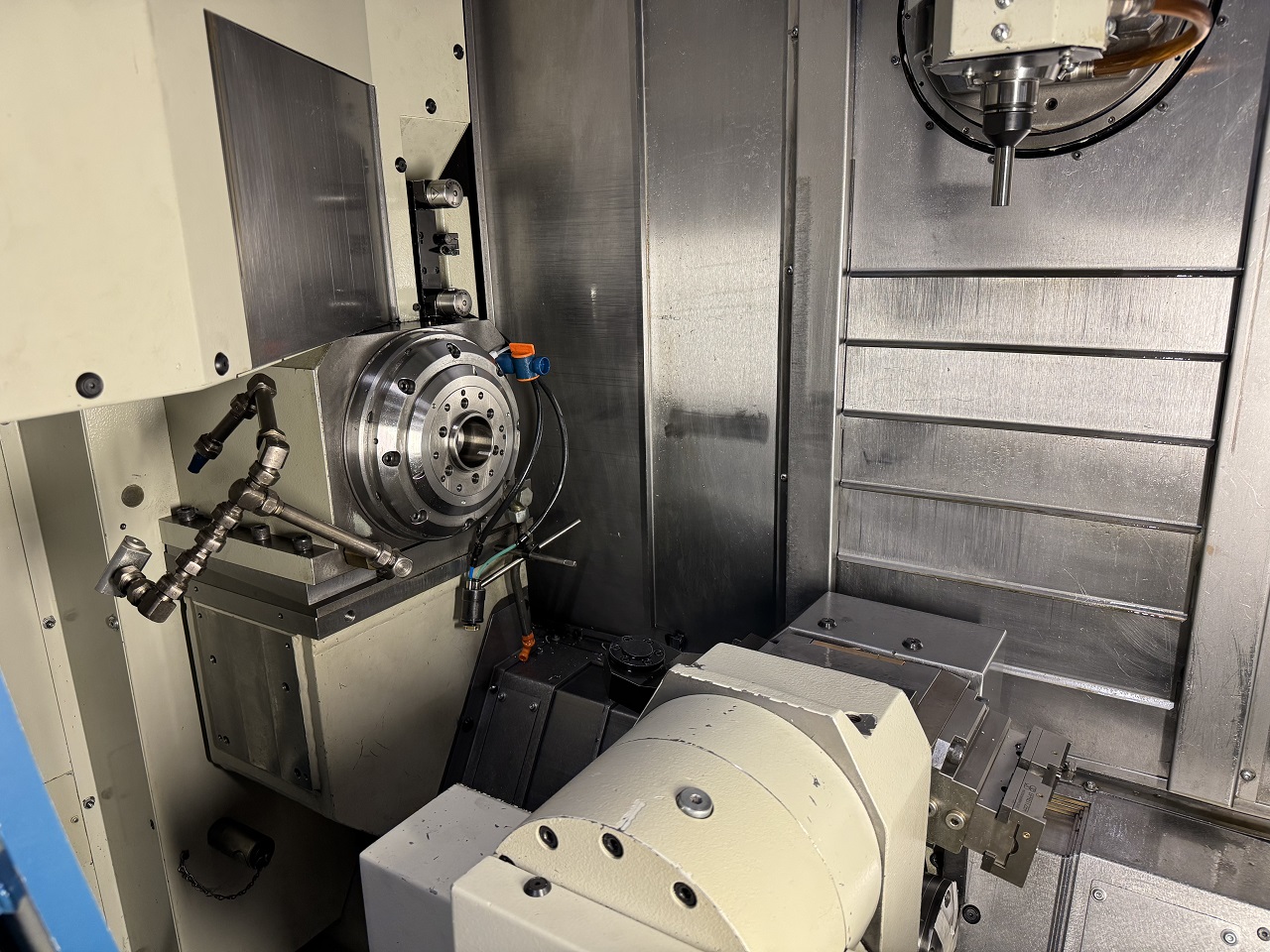

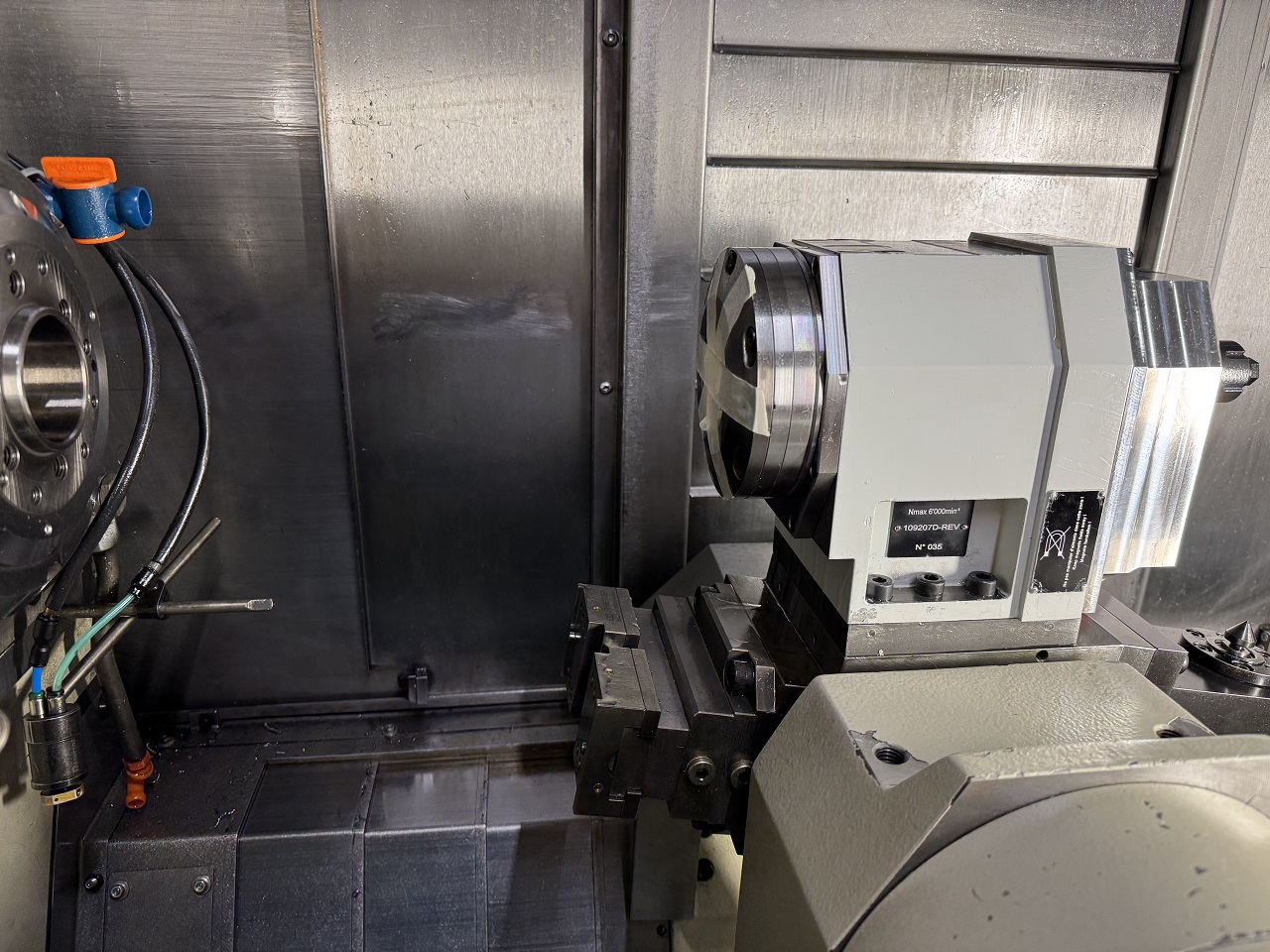

MACHINING CENTRE WILLEMIN-MACODEL W-508 MT

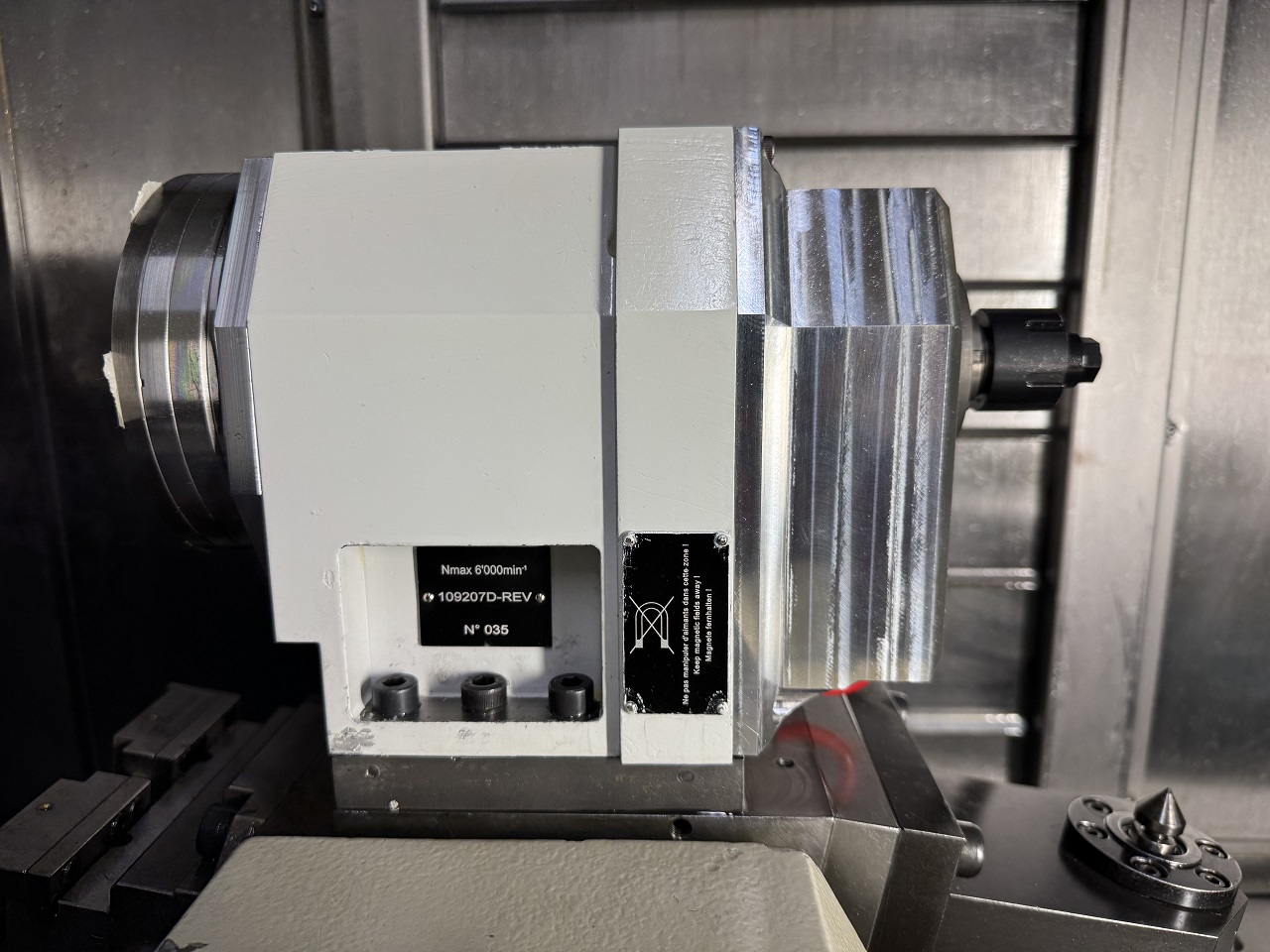

SKU: 2230001Machine partially overhauled by Willemin with new geometry and with new sub-spindle with 6'000 RPM.

New balls screws on axis X-Y-Z – Ready for production

5 axes – Fanuc 31i A5 – HSK40E – max 30'000min-1 – Year 2008

Request a quotation

Inventory no.2230001, machine comprising :

Fanuc 31i A5 control

HSK40E motorized milling spindle, MAX 30'000 min-1

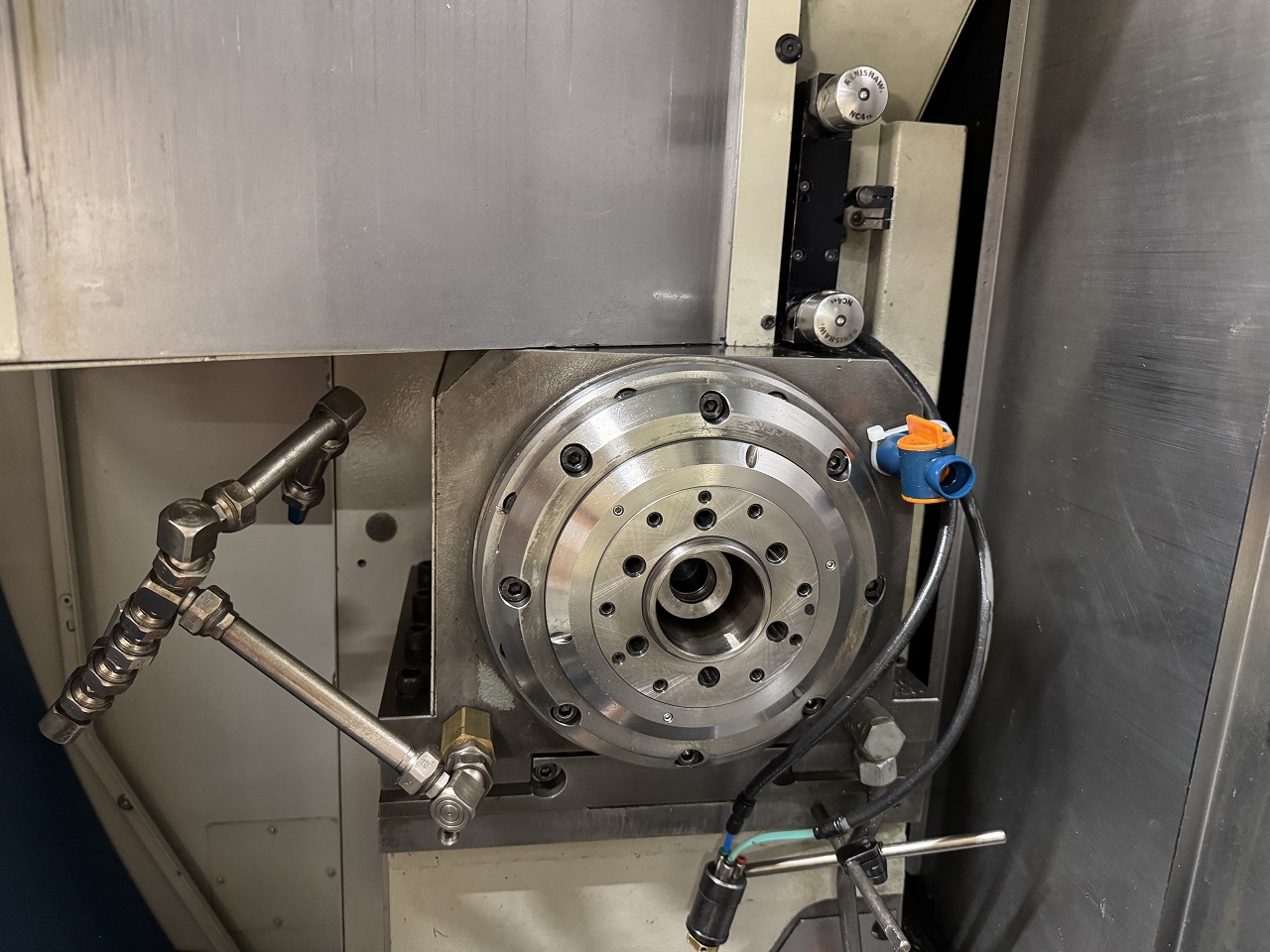

Touch test Renishaw NC4

Tool breakage monitoring – Renishaw NC4

Parts monitoring – Detector 101

Main spindle A – max Ø42 mm, max 6'000 min-1

Main spindle C – max Ø42 mm, max 3'000 min-1

Vice – Spreitzer centric clamping HZS 70-36 A WM – 400

Tailstock

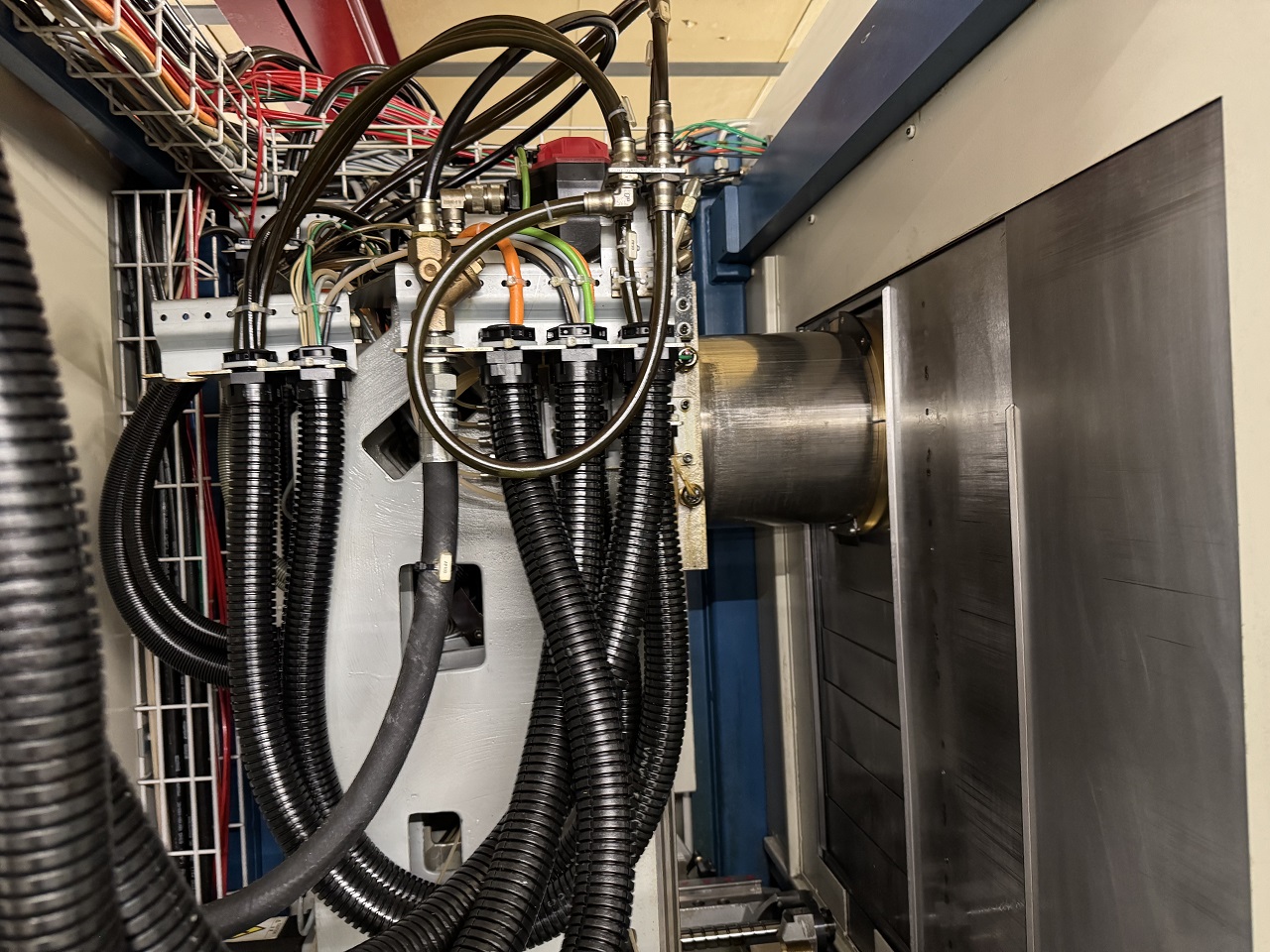

Spindle cooling unit – ARO version 1.1

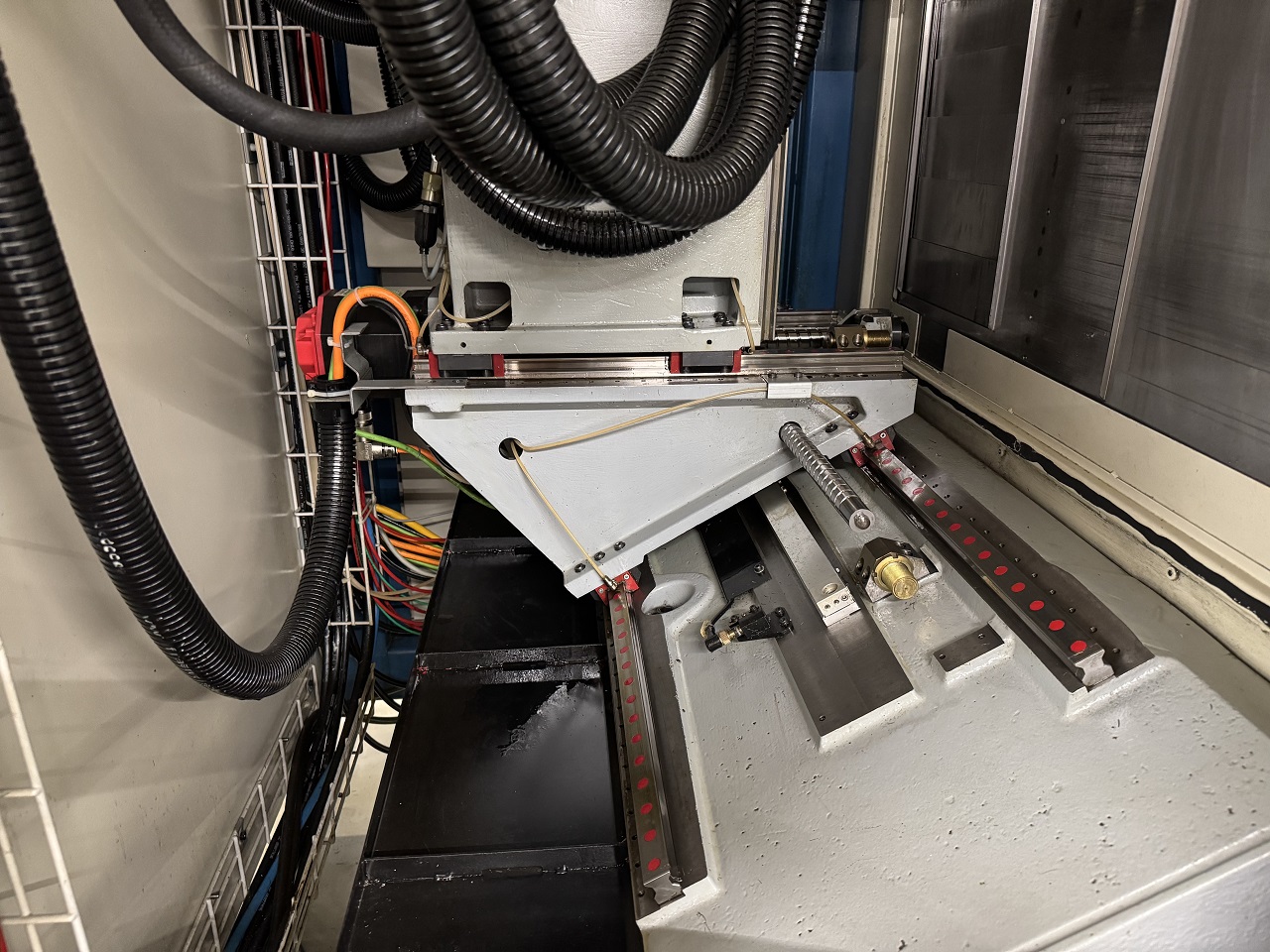

Feeder – LNS Super Hydrobar HS

Tool magazine – 48 PickUp stations

Rotating tools – Denitool Modulo D

Chip conveyor – NB 300 Cam – plate belt

Light signalling – Werma

Fire extinguishing – CO2 Kraft & Bauer – Not checked and without guarantee of operation. To be done by yourself.

Manufacturing origin CH

Voltage 3x400V / 60Hz ; 50 A ; 35 kVA

Netweight 2500 kg

Custom position 8457.1020

Dimensions 270x200x260 cm

TECHNICAL DATA

WILLEMIN MACODEL 508 MT

Fanuc 31i A5 control

X axis 450 mm

Y-axis 200 mm

Z axis 425 mm

B-axis -45° to +100

U-axis 300 mm

Tool magazine 48 PickUp stations

Main spindle A max Ø42 mm, max 6’000 min-1

Main spindle C max Ø42 mm, max 3’000 min-1

Motorized milling spindle HSK40E, MAX 30’000 min-1

errors and omissions excepted-data given without obligation

| Type | W-508 MT |

|---|