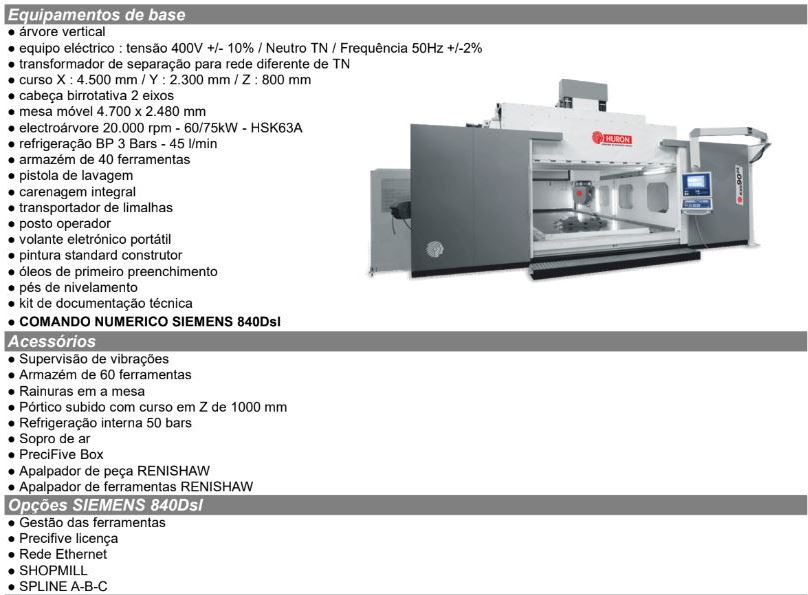

MACHINING CENTER “HURON” TYPE KXG 45-23

SKU: 2322011

Request a quotation

Inventory no.2322011, machine description :

Basic equipment :

Vertical axis

Electrical equipment: voltage 400V +/- 10 % / neutral TN / frequency 50Hz +/- 2

Isolating transformer for other mains than TN

Travels: X: 4500 mm / Y: 2300 mm / Z: 800 mm

2-axis bi-rotating head

Mobile table 4700×2480 mm

Electro-spindle 20'000 min-1

BP cooling 3 bar – 45 L/min

Tool magazine 40 tools

Washing gun

Integral fairing

Chip conveyor

Operator station

Portable electronic handwheel

Manufacturer's standard paint

Prime oil

Levelling feet

Technical documentation kit

Siemens 840Dsi digital control

Accessories :

Vibration monitoring

60 tool magazine

Slots in the table

Raised gantry for 1000 mm stroke Z

Internal cooling 50 bar

Compressed air

PreciFive Box

Renishaw workpiece probe

Renishaw tool probe

Siemens 840Dsi option

Tool management

PreciFive Licence

Ethernet network

Shopmill

Manufacturing origin FR

Voltage V

Netweight 65’000 kg

Dimensions 995x820x500 cm

TECHNICAL DATA

LINEAR AXES X / Y / Z

X stroke 4’500 mm

Y travel 2’300 mm

Travel Z 800 mm

Rapid feeds : X-Y = 60 m/min

Z = 45 m/min

Acceleration on axis X = 4 / Y = 4,5 / Z = 6 m/s2

TABLE

Surface : 4’700 x 2’480 mm

Load capacity 25’000 kg

Min/max distance spindle nose to table surface 150 / 950 mm

HEAD / ROTARY AXES B – C

B-axis +/- 95°

C-axis +/- 190°

Speed 60 min-1

PRECISION

Uncertainty: P (X / Y / Z) linear axes 25 / 10 / 10 µm

Repeatability: Ps medium (linear axes) 5 / 5 / 5 µm

Uncertainty: P rotary axes 10 sec.

Repeatability: Ps medium (rotary axes) 5 sec.

SPINDLE

Speed 20’000 min-1

Spindle taper HSK 63-A

Power – torque (S6 / S1) 75 / 60 – 75 / 60 kW – Nm

Characteristic speed 9’550 min-1

TOOL MAGAZINE

Number of pockets 40

Tool taper HSK 63-A

Tool size, length / Ø / kg. 300 mm / Ø 90 mm / 8 kg.

COOLANT UNIT

Flow – pressure : 10 L/min – 50 bar

Tank capacity 1’500 L

Errors and omissions excepted-data given without obligation

| Type | KXG 45-23 |

|---|