TURNING AND MILLING CENTER “BUMOTEC” TYPE S-191FTL-PRM

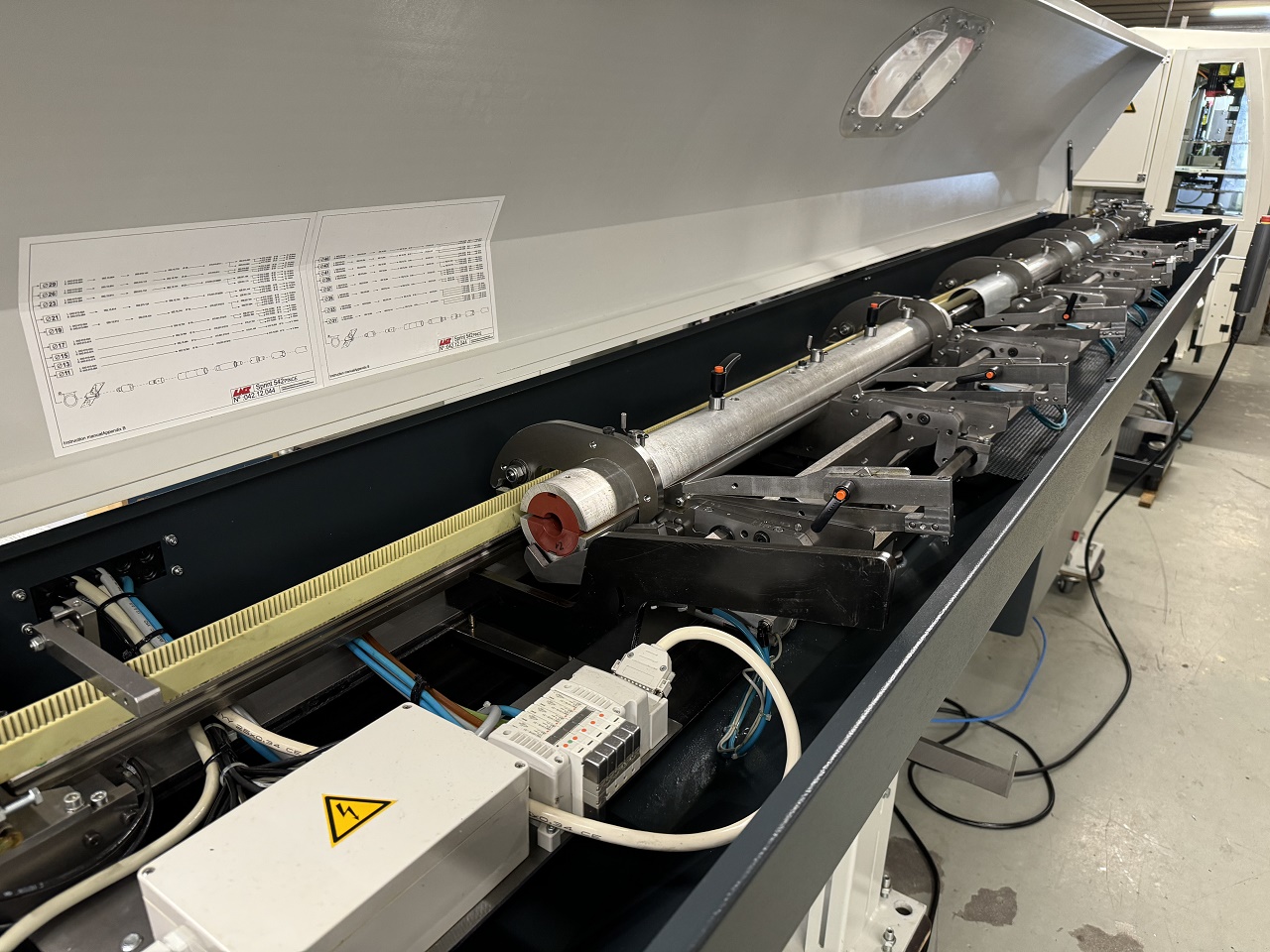

SKU: 2220113Year 2014 with LNS Sprint 542

Request a quotation

Inventory no. 2220113, Machine with :

Basic machine in artificially aged cast iron with reinforcing ribs.

Carriage with preloaded roller guides; ball screw with 20 mm pitch, driven by AC motors.

The electric main spindle (C-1) and the counter spindle (A) have a highly dynamic design and are technically identical.

The swivel axis (B) of the milling spindle is equipped with a direct drive.

Water-cooled high-precision electric milling spindle, hybrid bearing, oil-air lubrication, swivelling as B-axis.

HSK 40, type E or A, 30'000 min-1, internal cooling up to 80 bar possible in turning operation or when using pushing tools, the hybrid bearings are decoupled and cannot be damaged.

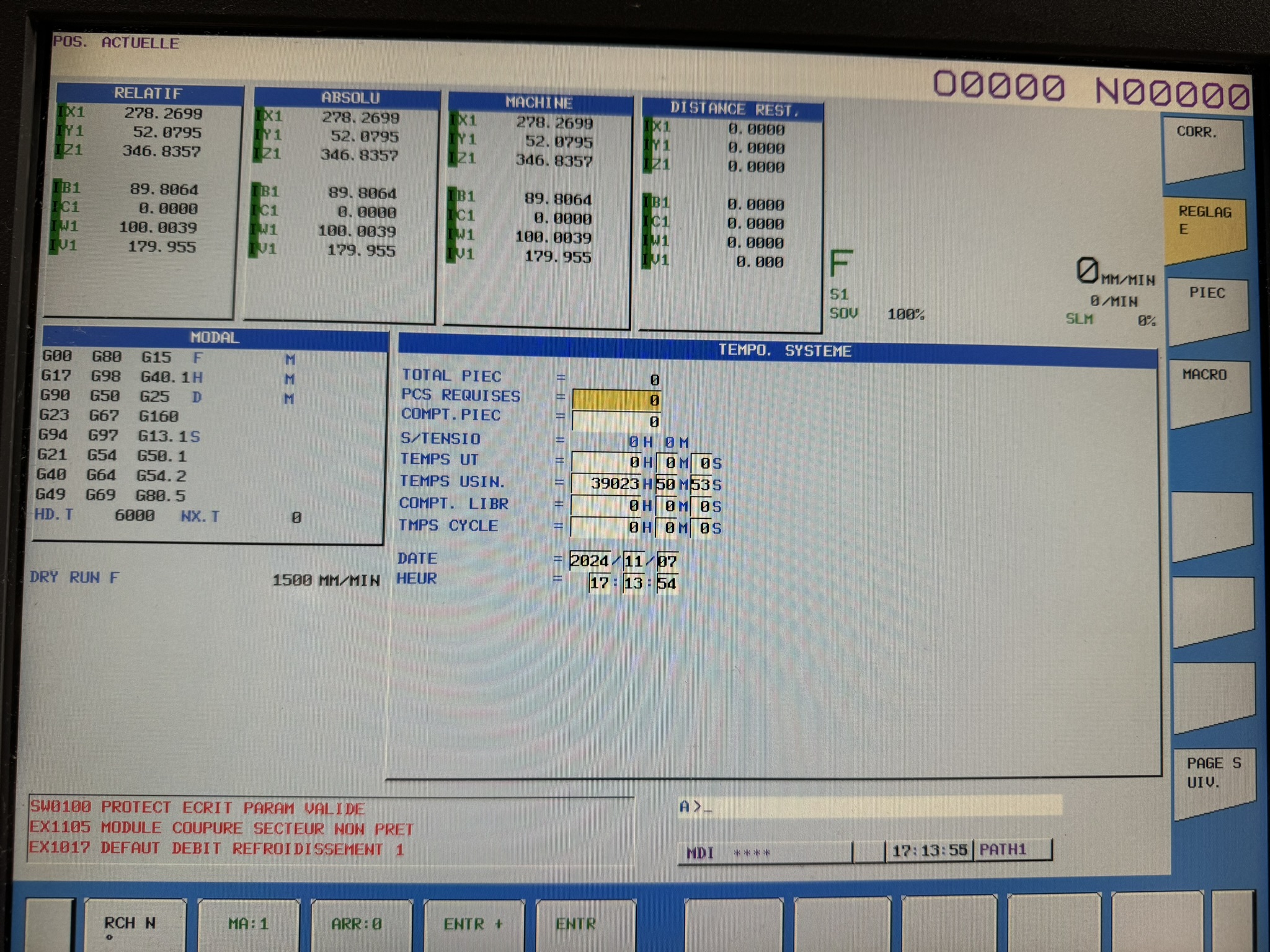

CNC control Fanuc series 31i

Fully enclosed working area with guaranteed tightness, completely separated from the technical side by means of metal lamellas.

Optimised chip flow, for optimum recovery of precious metals, simplified cleaning.

Coolant system with 160 L tank capacity ; pump with 40L/min. and 3 bar delivery capacity ; feed via ring nozzle at the spindle nose with 6 outlets.

3-channel recooling unit 4kW for cooling lubricant, spindles and the direct and linear drives.

Electrical control cabinet cooling

Automatic central lubrication ; monitored by CNC control (Attention : only lubricating oils approved by Bumotec are permitted)

Diagnostic system for error and alarm messages to simplify troubleshooting.

3-colour signal lamp for status indication.

OPTIONS :

Turn-mill function

4-position pick-up unit for backworking, with 2 parallel vice and 1 collet system

Increase of spindle clearance, C-axis to 50 mm (main spindle)

Unloading unit with backworking

Tool measurement Renishaw TS 27

Spindle probe Renishaw OMP400, with automatic correction on the tool after scanning on the part

Tool magazine capacity increased from 30 to 60

Spindle adaptation / integration rotary coupling for IK

IK high pressure unit type Hydrofluid HP 3, max 100 bars, tank 400 L

Parts unloading conveyor

Scraper belt chip conveyor LNS MH 500

Manufacturing origin CH

Netweight 4200 kg

Voltage 3/N/PE/400V/230V 50HZ

Dimensions 220X190X199 cm (height 250 with aspi.)

TECHNICAL DATA

Model S-191FTL-PRM Ø 50 mm

MACHINE BASE

Axis travel

Vertical milling axis Z = 200 mm

Cross milling axis Y = 200 mm

Longitudinal milling axis X = 410 mm

Power / thrust force

Z-Y : 2.5 kW / 550 daN

X 4.5 kW / > 550 daN

Travel speed X-Y-Z 40 m/min

Acceleration 10 m/s2

Resolution X-Y-Z 0.0001 mm

Measuring system glass scale

MAIN SPINDLE C (horizontal turning axis)

Power 15 kW

Torque / peak 22 / 28 Nm

measuring system direct

Resolution 0.0001°

Accuracy 0.001

Bar passage : Ø 32 mm (option 50 mm)

Turning speed 72’000°/min

Clamping force, turning : 4’900 N at 6 bar

SPINDLE INCLINATION MACHINING B

Power 4.3 kW

Torque / 119 / 226 Nm

Angular displacement -25° / +115

measuring system direct

Resolution 0.0001°

Accuracy 0.001

Rotational speed 36’000°/min

Locking torque 200 Nm

MACHINING SPINDLE

Power 8 kW

Torque S1 = 9.5 Nm

S6 = 11.5 Nm

Max. speed 30’000 min-1 (40’000 min-1 optional)

Tool clamping force : 1’000 N

Clamping torque : mechanical clamping with spur gear

Tool taper HSK-40 (A or E)

Spindle lubrication : 30 to 100 bar (optional)

TOOL CHANGER

Number of tools : 30 (option 60)

Number of indexed tools : all

Tool change time 1.2 sec.

Chip to chip time 4.4 sec.

Max. tool diameter Ø 40 mm

(80 mm if adjacent station empty)

Max tool length : 130 mm

Max. tool weight 1.5 kg

MISCELLANEOUS

Installed power : 25 kVA

Operating voltage 3/N/PE/400V/230V 50 Hz

Pneumatic 6 bar (dry air)

CNC CONTROL : Fanuc 31i

15” colour screen

Alphanumeric keypad

Control panel with :

1 key switch for functions

1 potentiometer for feed rate 0 – 120

1 spindle rpm potentiometer 50 – 120 % 1 quick selection key for machine functions

1 quick selection key for machine functions

1 built-in electronic handwheel

CNC options

Data server with ATA Flash, 1GB memory capacity

J947 1 MB RAM memory

S677 TCPC (tool centre point control for 5-axis machining)

S808 Al nano HPCC (Al high precision contour control ll)

J930 tool tip radius compensation

J893 coordinate system rotation

J819 Helix interpolation (cylindrical)

J953 memory capacity for 1000 programs

J828 tapping without compensation chuck

S615 radius and chamfer insertion

J894 coordinate system for workpiece

S993 workpiece setting error

R522 inclined plane machining control with guidance

Interfaces

Bumotec specific programming to avoid collisions as much as possible.

Simplified tool management to avoid input errors.

Tool management with threshold value, change according to the number of parts or life.

Automatic tool setting on the machine to simplify tool handling.

Part counter and production management.

Y-axis (horizontal cross milling axis)

Stroke 200 mm

Power / thrust force 4.8 kW / 240 daN

Resolution 0.0001mm

Max. travel,V1 50 m/min

Max. travel,V2 20 m/min

Measuring system glass scale

Z-axis (horizontal longitudinal milling axis)

Travel 400 mm

Resolution 0.0001mm

Max. travel,V1 50 m/min

Max. displacement,V2 20 m/min

Measuring system glass scale

Including cooling unit 8kW

Integration of an emergency braking system

errors and omissions excepted-data given without obligation

| Type | S191FTL-PRM |

|---|