NC TURNING CENTER “SPINNER” TYPE TM

SKU: 22200947 axes, control Siemens Sinumerik 840D

Request a quotation

Inventory no.2321018, machine equipped with :

Chip conveyor

Preparation for bar feeder

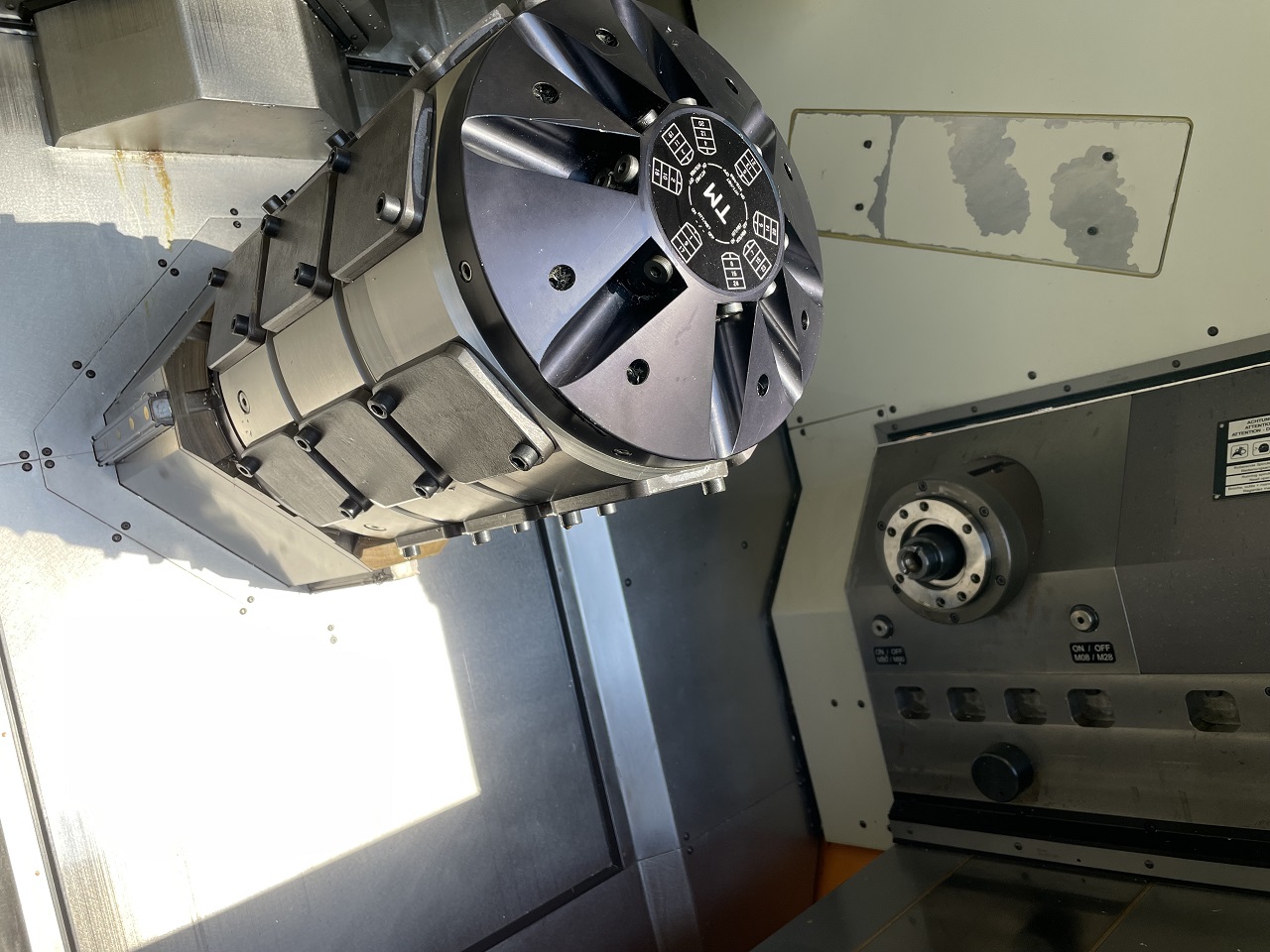

Tool holders :

6 fixed drills ER32

8 turning tool holders

5 live tool holders ER32

4 live tool holders ER25

6 live tool holders ER20

Manufacturing origin CE – Germany

Voltage 400V

Netweight 7500 kg

Custom position 8458.91 20

Dimensions 2,9 x 2,3 x 2,3 m.

TECHNICAL DATA

AXES

Maximum travel X-axis 400 mm

Maximum travel Y-axis 300 mm

Maximum travel Z1-axis 475 mm

Maximum travel Z2-axis 475 mm

Relative positions B-axis 0,0001 – 360°

Relative Position C1/C2-axis 0,0001 – 360°

WORKPIECE

Maximum cubic dimensions 80x80x80 mm

Maximum weight 5 kg

TURRET

Number of stations 24

Number of controlled stations 18

Number of steady stations 6

Maximum tool attachment (round) Ø 20 mm

Maximum tool attachment (square) 16×16 mm (20×20)

Maximum trajectory of turret above tool’s point : 500 mm

Rotation speed of live tools 1-9000 min-1

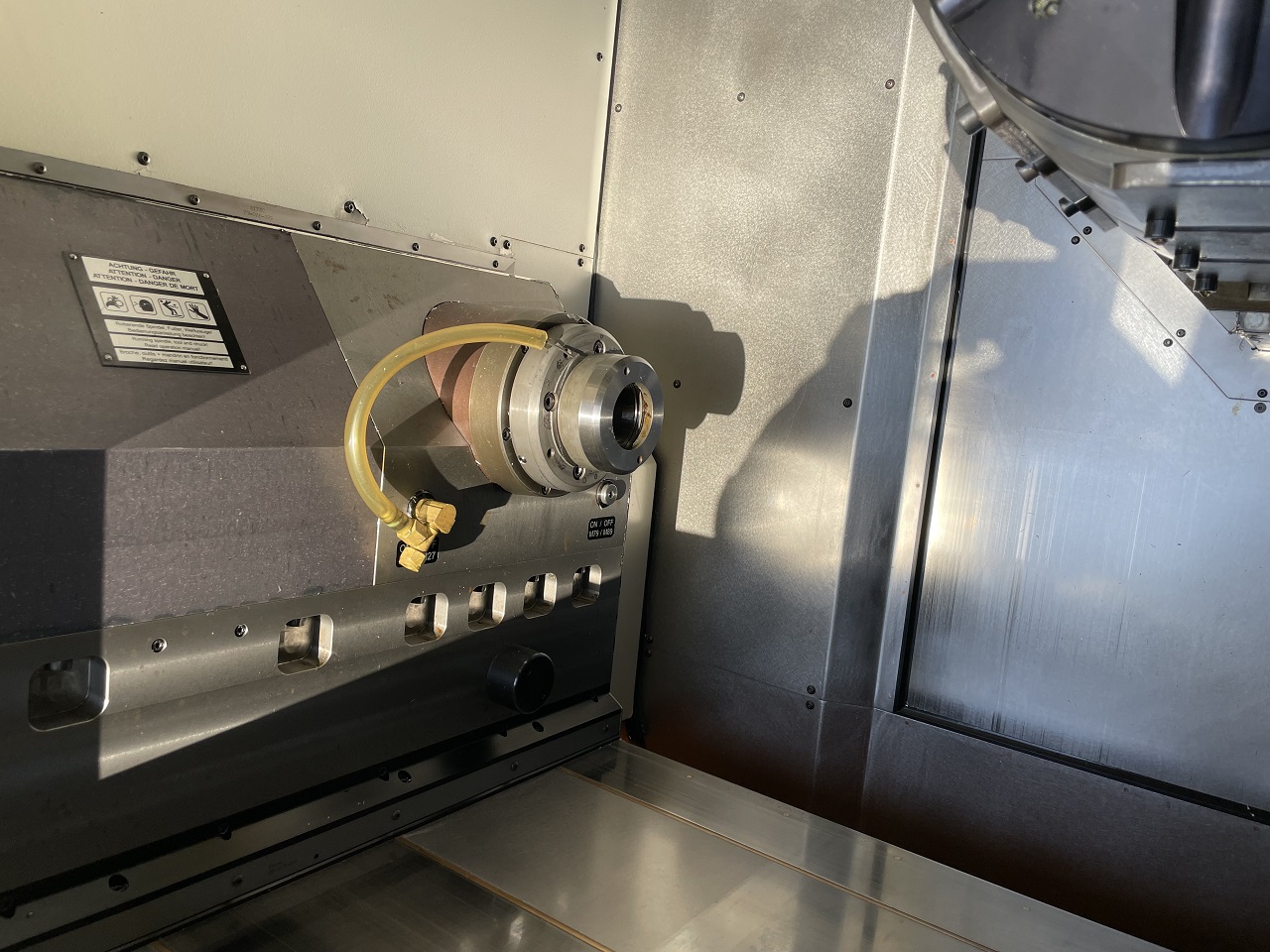

SPINDLE

Maximum rotation speed 6000 min-1

Maximum bars diameter Ø 42 mm

Maximum forced chuck clamping 140 mm

BARS MACHINING

Maximum bar length for bar’s feed 1000 mm

Maximum piece size for the bar taker Ø42 x Long.100 mm

Maximum diameter of taker’s collets 42 mm

Pulling and pressure force of clamping cylinder 20000N

FEEDS

X-axis advance force abt.895 daN

Y-axis advance force abt.895 daN

Z1-axis advance force abt.895 daN

Z2-axis advance force abt.895 daN

Fast moves axes X/Y/Z 20 m/min

Motor’s torque of tool control 2,4 Nm

Spindle S1 / Spindle S2 70Nm

COOLING (values only as indication)

Capacity of pump submerged inside chips conveyor 10 l/min for abt. 4,5 bar

80 l/min 3,2 bar

150 l/min 0,7 bar

Capacity of overpressure pump inside conveyor 10 l/min 13,2 bar

50 l/min 9 bar

90 l/min 1 bar

Lubricating coolant volume inside conveyor abt.134 L.

Coolant volume inside cooling aggregate : 45 L.

NUMERIC CONTROL Siemens 840D

MACHINING PRECISION

Resolution axes X/Y/Z 0,1 µm

Resolution axe B 0,0001°

Resolution axe C 0,0001°

Positioning precision 5 µm

Repeatability 0,6 µm

Maximum error on workpiece’s concentricity 0,5 µm

ELECTRIC

Spindle 1 / Spindle 2 (at 100%) 11 kW

Spindle 1 / Spindle 2 (at 40 %) 15 kW

Advance motors axes X/Y/Z1/Z2 1,3 kW

Axis B 1,3 kW

Tool control 2,3 kW

Hydraulic pump 7,5 kW

Hydraulic back movement 0,75 kW

Cooling aggregate fan 1 / 2 0,18 kW

Circulation pump of cooling aggregate 1,1 kW

Compressor of cooling aggregate 2,2 kW

Chips ejector 0,25 kW

Emulsion pump 1 1,1 kW

Emulsion pump 2 2,2 kW

Operation tension 400 V

Network frequency 50Hz (60option)

Control tension : 24V DC

Absorbed power 35 kW

Nominal current 63A

Connecting réseau TM / TT / IT

PNEUMATIC

Maximum operation pressure 10 bar

Normal operation pressure 6 bar

Minimal operation pressure 5 bar

Air output env. 150 L/min

Valves tension 24V DC

Oil-mist lubrication tank capacity 12 L

Quality level 2 selon Pneurop6611

NOISE LEVEL

Normal use 78—80 dB

errors and omissions excepted-data given without obligation

| Type | TM |

|---|