CCN LATHE SCHAUBLIN TYPE 180-CCN R-T A2-5

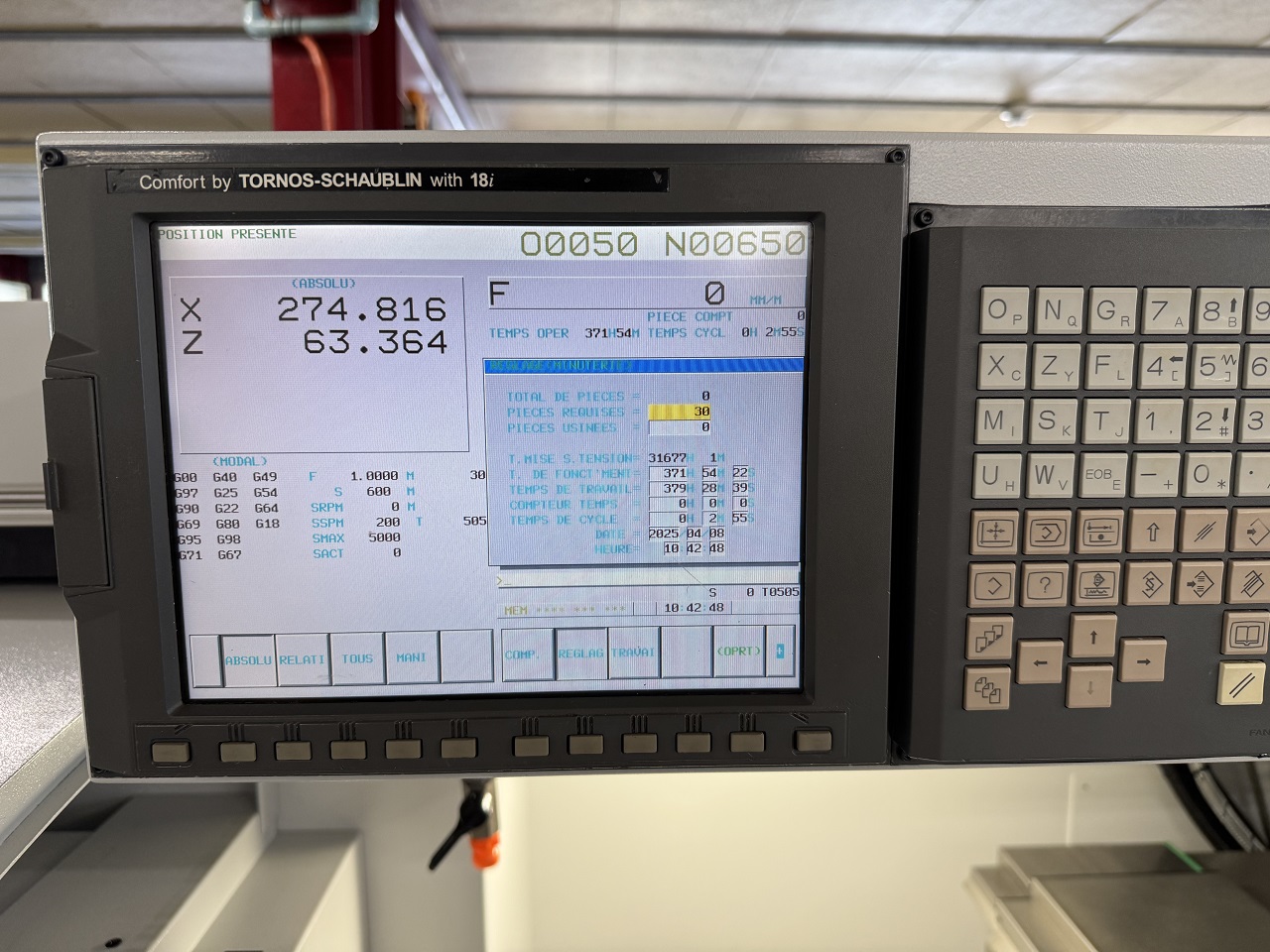

SKU: 2230052Year 2000 with Fanuc 18i- Spindle A2-5 – revolver 8 pos. VDI 30

Completely overhauled:

Mechanics, geometry, hydraulics and electrical parts (checked and/or replaced)

Spindle

Dismantling, cleaning parts, replacing worn and defective parts, replacing belts, dismantling spindle, replacing seals and O-Ring + adjustment. New paintwork.

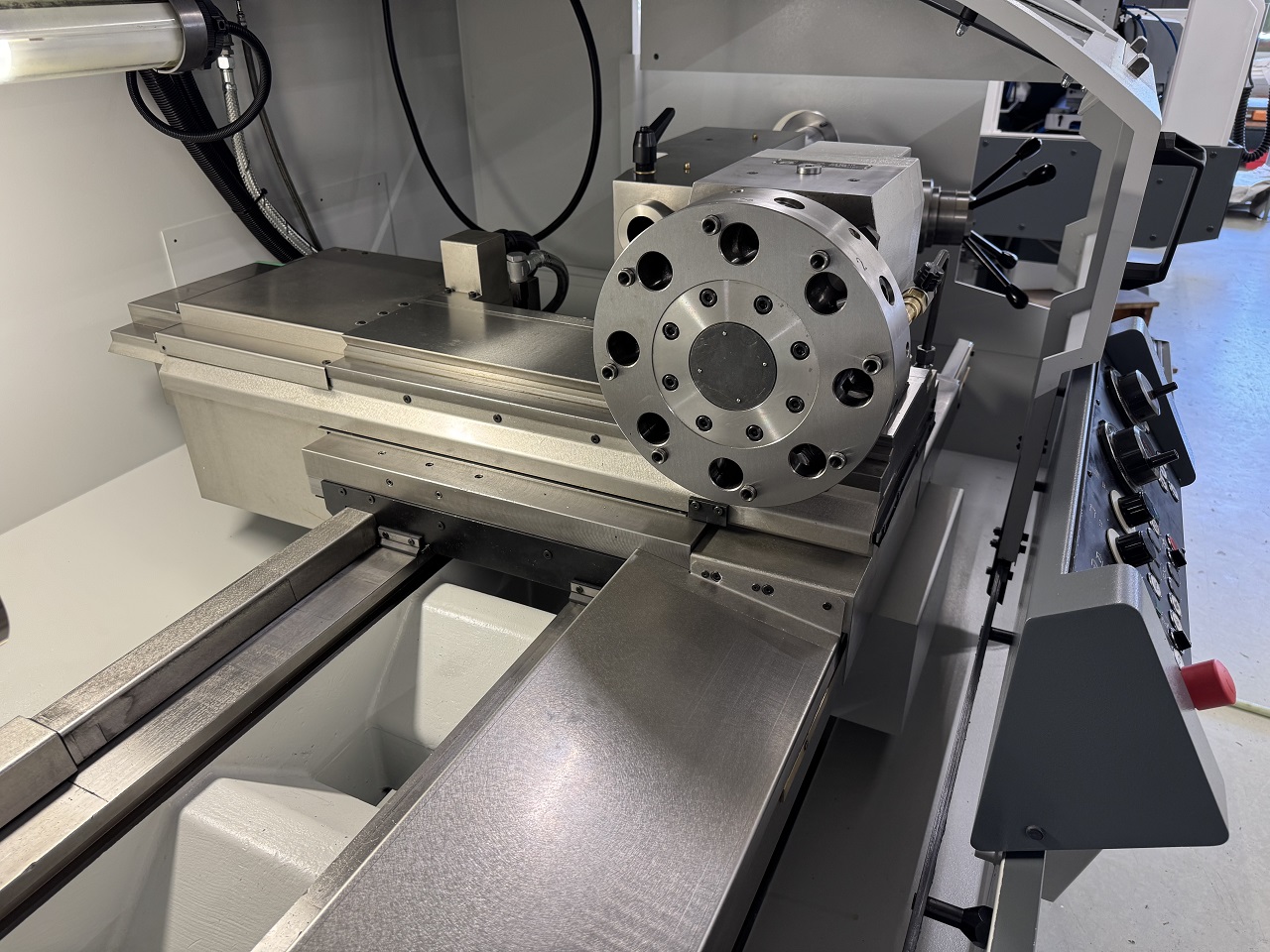

Revolver

Dismantling, cleaning of parts, replacement of worn and defective parts, new paintwork and grinding of faces.

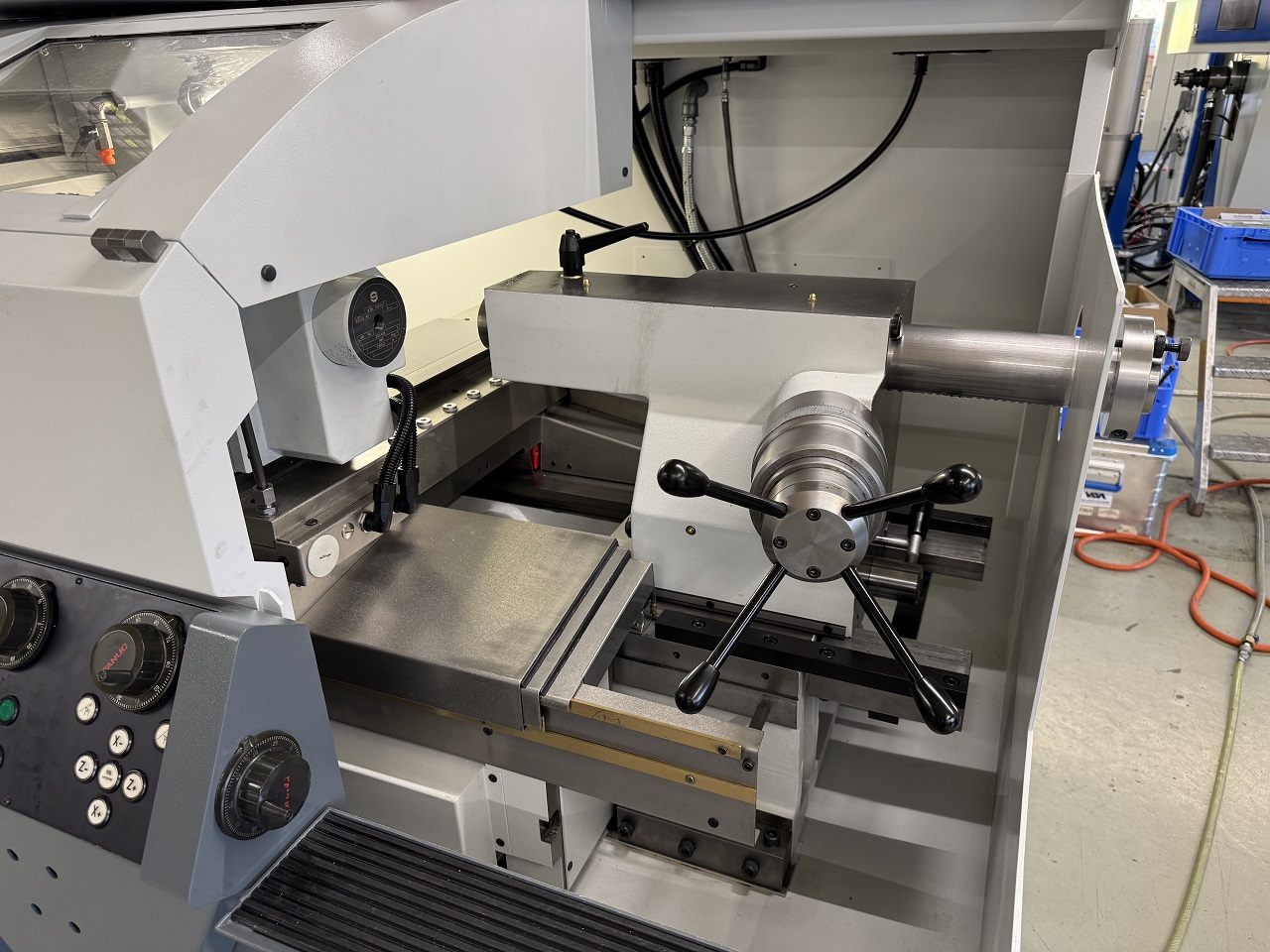

Tailstock

Dismantled, checked and overhauled. New paintwork

Hydraulics and pneumatics

Dismantled, checked engine, replaced pipes, defective and worn parts.

X-axis

Dismantling, replace worn parts such as O-Ring, seals, segments. New ball screw and pad

Z-axis

Dismantling, replace worn parts such as O-Ring, seals, segments. New ball screw and pad

Electrical cabinet

Complete check, replacement of various relays.

Paintwork

Colours: White RAL 9003 and grey RAL 7011

Geometry according to manufacturer's protocol.

Inspection and cleaning of various accessories

Request a quotation

Inventory 2230052 including :

– 1 Fanuc 18i control unit

– 1 A2-5 spindle head

– 1 VDI 30 8-position revolver

– 1 Cross headstock 180-65.100

– 1 Equipment for using B-45 collets 180-27.205

: On A2-5 spindle with drawbar 180-27.209

– 1 Adjustable stop and extractor B45 ref 180-27.185

– 1 Set of 57 B-45 collets

– 1 RHU manual 3-jaw chuck Ø 200 mm passage 51 mm A2-5 ref 4000.00083

: With 1 set of 3 reversible jaws, 1 set of basic jaws with inserts

– 1 manual chuck with 4 FN jaws Ø 200 mm mm passage 55 mm A2-5 ref 4000.00086

: With 1 set of 4 drilling jaws and 1 set of 4 turning jaws

– 5 levelling elements

– 1 coolant device

– 1 stand alone 180-60.005

– 3 rectangular transverse toolholder, left short Forme B2 ref 4100.00100

– 1 toolholder for carbide indexable dril bore 20 mm forme E1 ef 4100.00105

– 1 collet holder ESX-25 forme E3 with nut EX25 and 1 collet Ø 4 ref 4100.00116

– 1 boring bar holder, bore Ø 10 mm ref. 4100.0109

– 1 dito Ø 12 ref 4100.00110

– 1 dito Ø 16 ref 4100.00111

– 1 dito Ø 20 ref 4100.00112

– 1 dito Ø 25 ref 4100.00113

– 1 coolant device

OPTION

1 hinged steady rest 3 dogs for Ø 30 – 120 mm ref 180-70.200 chf. 2'500.– + VAT

Manufacturing origin Swiss

Voltage 380/50/3

TECHNICAL DATA

Capacities :

Maximum turning diameter 330 mm

Maximum swing over carriage 160 mm

Height of centres over carriage 83 mm

Maximum swing over bed 430 mm

Turning length between centres (according to equipment) 650 mm

Headstock :

Standardized spindle nose, for use of several collets and jaw-chucks by means of adapter sleeves

Accessories for SCHAUBLIN collets B45/F48

Maximum throughbore, dia. 36 mm/42 mm

Diameter of standard chck 170 mm

Direct AC motor drive, power at 100%/50% duty factor 15/18,5 kW

Max. torque at 100%/50% duty factor 135/165 Nm

Spindle speeds, stepless 5000 min-1

C Axis :

Pneumatic closing Cylinder, maximum 5 bar, maximum clamping force 2700 daN

Apron and carriage :

Transverse stroke (X-axis) 240 mm

Rsolution, on radius 0,0005 mm

AC motor drive, torque 3 Nm

Ball screw, dia. x pitch 32 x 5 mm

Longitudinal stroke (Z-axis) 720 mm

Resolution 0,001 mm

AC motor drive, torque 6 Nm

Ball screw, dia. x pitch 32 x 10 mm

Feeds :

Working feeds, X-/Z-axis, stepless 0-5000 mm/min

Rapid feed, X-/Z-axis 8/10 m/min

Feed pressure, X-/Z-axis 420/670 daN

Tooling system Turret :

Number of tool stations 8

Standardized fixing of toolholders VDI 30

Maximum tool size 20 x 20 mm

Integrated cooling

Indexing in both senses of rotation

Coolant supply :

Capacity of coolant tank 120 litres

Pump power 10 l/min

Pressure 5 bars

errors and omissions excepted data gived without obligation