Willemin-Macodel machine tools : Swiss precision machining

The Swiss expertise of Willemin-Macodel machine tools

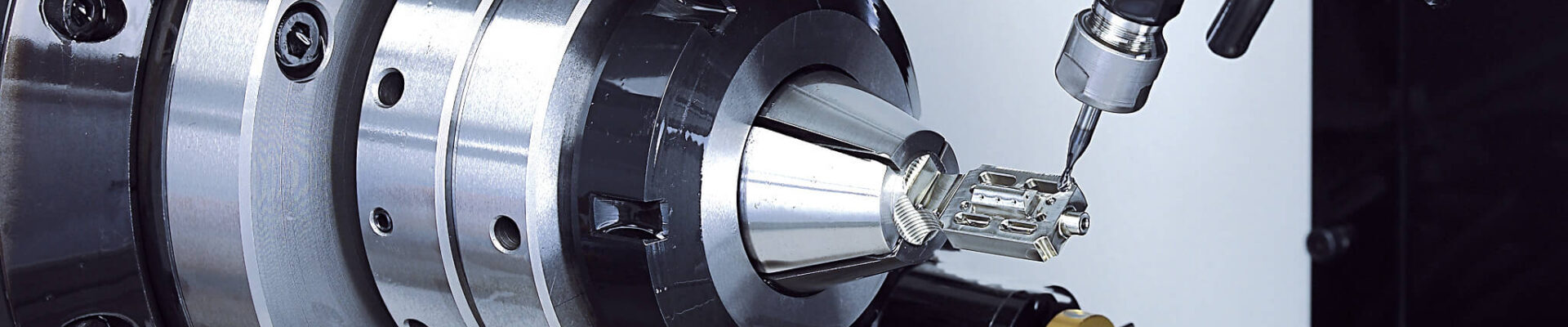

Willemin-Macodel machine tools embody the brand’s expertise, renowned for its mastery of high-precision machining and the stability of its solutions.

Based in Switzerland, the company has a long-standing history of collaboration with highly demanding sectors such as watchmaking, medical technology, micromechanics and instrumentation. These fields require processes capable of reproducing results with micron-level accuracy, even when geometries become highly complicated.

Willemin-Macodel headquarters building, Delémont

A range of machines adapted to every need

The Willemin-Macodel range comprises machines capable of meeting today’s industrial needs, whether in terms of precision, flexibility or machining capacity. Each model has its own strengths, allowing each workshop to find a solution tailored to its applications and requirements.

An architecture designed for stability

The machines are based on a rigid mechanical structure capable of absorbing repetitive stresses. Thanks to this stable foundation, consistent precision is guaranteed, even during prolonged machining operations or when materials react to heat.

A multi-axis kinematic system to reduce the need of repositioning

Models equipped with 4 or 5 axes facilitate access to the different faces of a part without requiring multiple setups. This approach reduces rework, improves overall precision and allows for the production of complex shapes in a single configuration. It is particularly well-suited to workshops that work with small volumes while demanding consistent quality.

Effective mastery of technical materials

Machine tools offer the robustness, thermal resistance and power needed to machine demanding materials such as:

- titanium

- stainless steel

- special alloys

- hard materials for watchmaking and micromechanics

This mastery makes it possible to obtain precise contours and a regular surface finish, even during delicate or repetitive operations.

One of the most versatile Willemin-Macodel machine tools

The W-508 MT stands out for its remarkable versatility in precision machining. This turning and milling machine combines power and stability, offering a wide range of applications. Its HSK40E spindle, capable of reaching 30,000 rpm, easily handles high-speed machining operations. The two main spindles can accommodate workpieces up to Ø42 mm, increasing production capacity. The 48-tool magazine facilitates quick tool changes and optimises workflows.

A technology designed for small production runs, combining precision and efficiency

The W-408 B brings a different approach. More compact than the W-508 MT, it is aimed at workshops that work on small parts or repetitive series.

Among its strengths:

- A small footprint, ideal for confined spaces

- Kinematics adapted for bar work, with 360° rotation (A) and 0° to 90° rotation (B)

- Inherent capacity for small bar production runs

- A rigid structure, efficient for technical shapes

- A more targeted approach for operations where precision and repeatability are paramount

An offer that adapts to diverse environments

Thanks to its expertise and carefully selected range of Willemin-Macodel machines, Scemama offers solutions capable of meeting a wide variety of industrial needs. The product range covers both high-speed workshops and environments requiring greater flexibility.

Scemama therefore provides a selection of carefully chosen models, allowing each workshop to find the solution that best suits its specific needs.