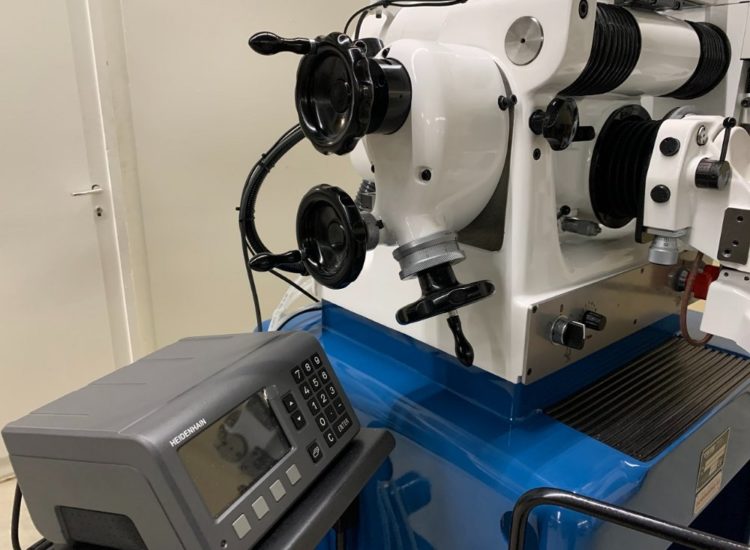

EWAG WS 11 Universal Grinder

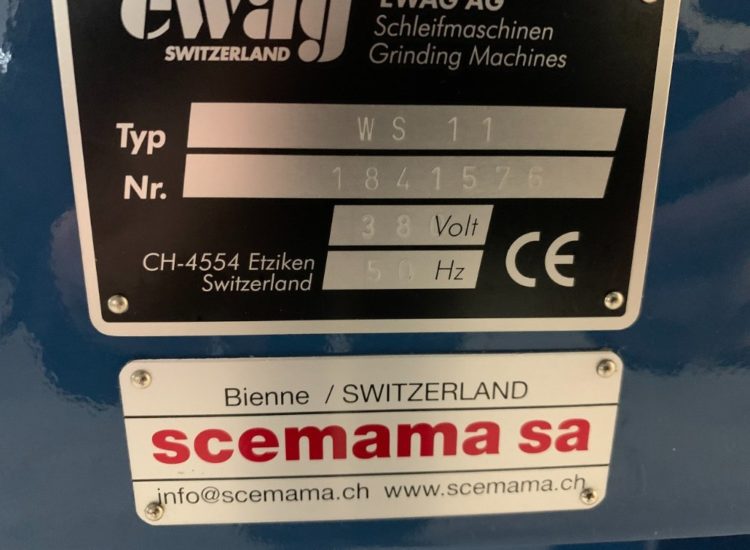

The WS 11 machine is a tool grinder or universal grinder from the EWAG brand.

Scemama SA has extensive expertise in the WS 11 as we have been servicing this model for many years. First we buy used versions, then we proceed to do a complete overhaul in our workshop. To refurbish the machines the grinders are disassembled, the parts changed, and the painting refreshed. Our skills allow us to provide our clients with quality after sales service.

Discover the EWAG WS 11 machine

This universal grinder specialises in the machining of high precision tools, regrinding of tools and the machining of production parts.

It is therefore used in both production plants and grinding companies. It also benefits from the new geometrical tolerance of the new EWAG machines.

A ground-breaking grinder

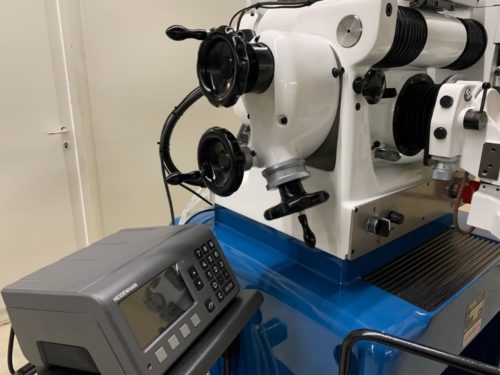

Grinding and cutting tools have become an easier and more precise task thanks to the WS 11. The entire grinding machine fits within in your field of vision and all axes of the machine are within reach. This EWAG universal grinder can be operated with ease and precision,thanks to an optimal ergonomic design.

Swiss precision: the WS 11 tool grinder allows for the machining of tools with a diameter of up to 25 mm. This universal grinder is therefore perfect for use with precision tools.

WS 11 universal grinder uses

The EWAG tool grinder excels in the production and grinding of small rotationally symmetrical tools. It can also produce small batches of precision parts. Its extreme precision allows it to reach a diameter of up to 25 mm. In terms of material, its suited for HSS and carbide.

Advantages of this grinding machine

We appreciate the WS 11 universal grinder for its compact, unobtrusive design. The machine frame is made of solid aluminium and grey cast iron for optimum durability.

It also has linear axes X, Y, (V) and Z as well as rotary axes A, B, C, and D for maximum flexibility in your work. These axes are positioned in an ergonomic way so as to ensure that the operation of the machine does not result in fatigue.

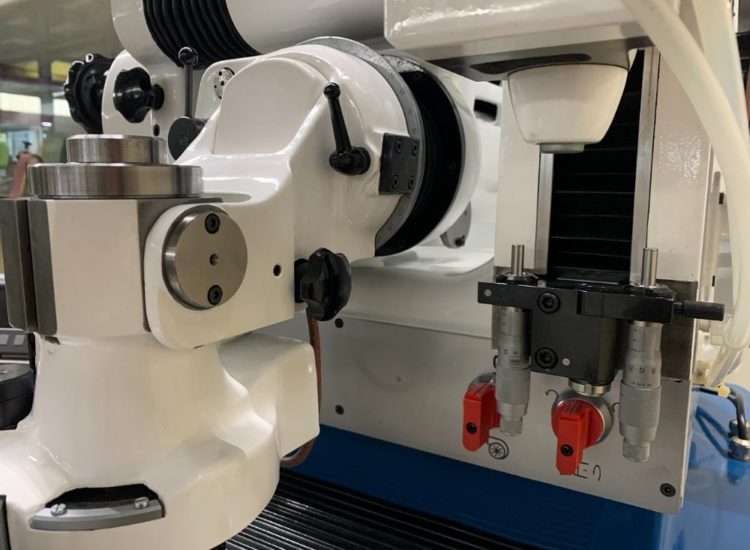

In addition, its measuring optics makes the chip removal process visible, allowing you to verify the measurements.

Another advantage: its hydrostatic grinding wheel spindle with constant thermal expansion which offers a very high level of precision in a durable manner. The EWAG WS 11 also has a large range of accessories which allows it to adapt to all kinds of tasks.

A machine suited for watch making

The manual EWAG WS 11 universal grinder has already made a name for itself in the Swiss watch-making industry. Thanks to its four linear axes and its three or four rotary axes, it allows for the grinding of filigree and complex geometries. It carries out this task with extreme precision, and with a single clamping device. In addition to its precision which is perfect for the watch-making industry, it is also easy to use.

The geometry of the EWAG WS 11

This expert tool grinding machine’s kinematics is well designed. That is why it can reproduce complex geometries with such precision.

The WS 11 also represents highly precise measurement values. In addition, it grinds and measures tools with the same clamp, including for cylindrical, helical and conical geometries. This is important for quality control.